Definition

Slip Rings, also known as collector rings, conductive rings, rotary joints, rotary electrical interfaces, commutators, adapters, and other names, are electromechanical devices that allow for the transmission of power or signals from a stationary structure to a rotating one.

Characteristics

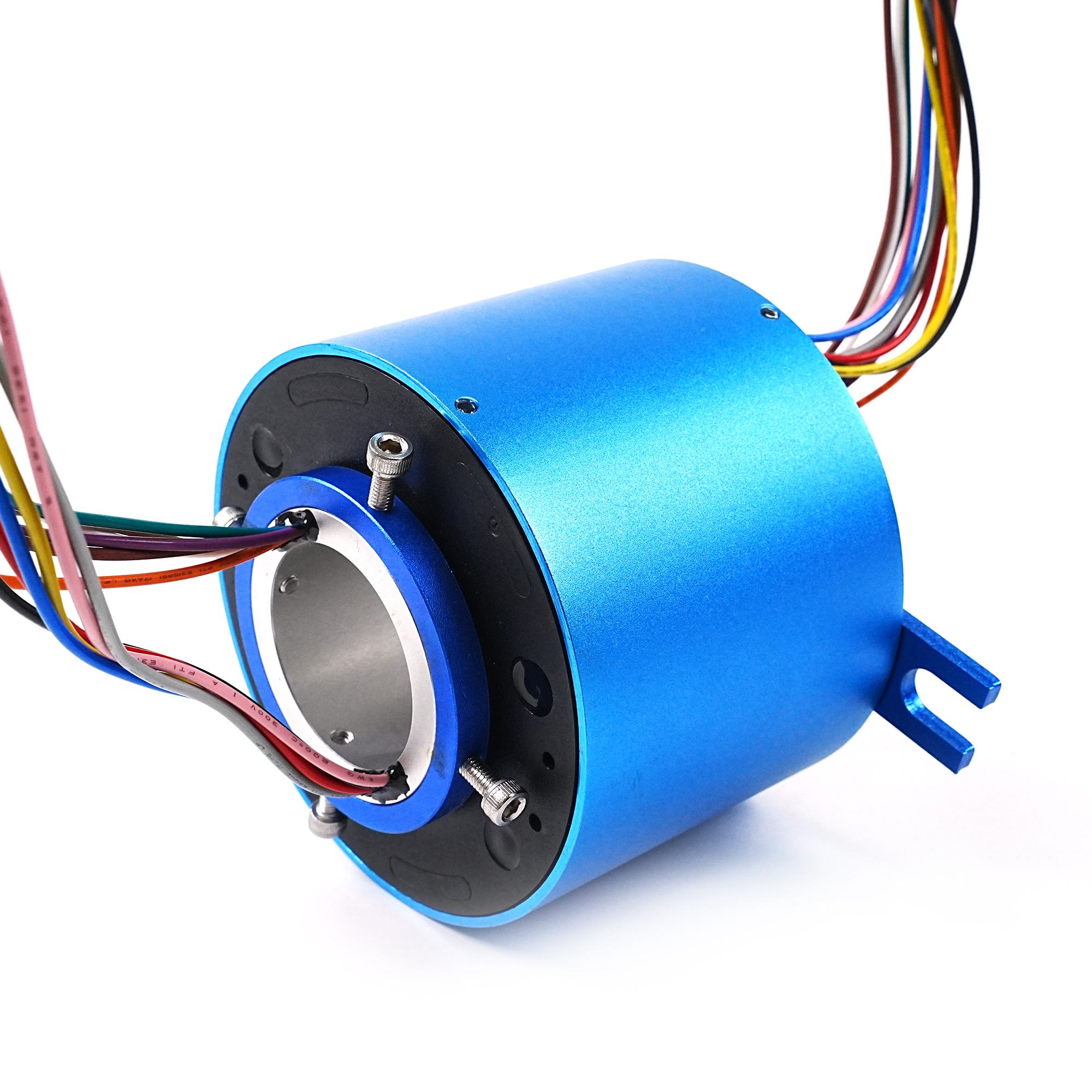

Structural Features: Slip Rings typically consist of a rotating part (rotor) and a stationary part (stator). The rotating part connects to the rotating structure of the equipment, while the stationary part connects to the fixed structure and supplies power to it.

Material Features:Slip rings use elastic materials to make the brushes, and the sliding contact surface uses conductive rings. The brushes are typically composed of spring-like wire contacts or brushes, providing constant pressure to maintain the electrical connection with the contact rings.

Transmission Features:Slip Rings accurately transmit various signals, such as Ethernet, USB, RS, Canbus, FireWire, as well as signals for servo motors, encoders, strain gauges, thermocouples, etc. They are suitable for situations requiring continuous rotation while maintaining power and/or data transmission.

Functions

Functions

Parameter Drawings

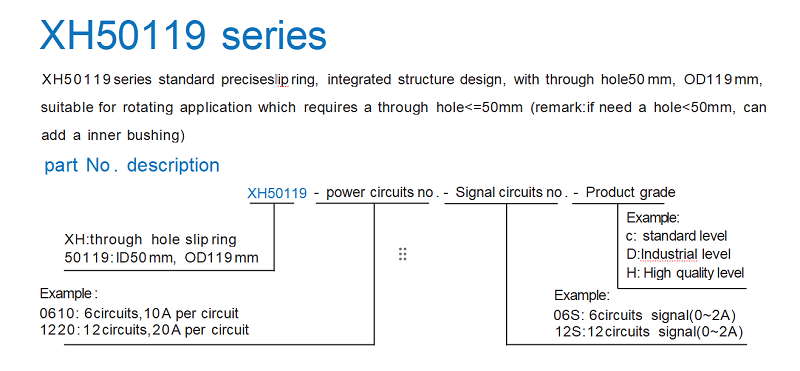

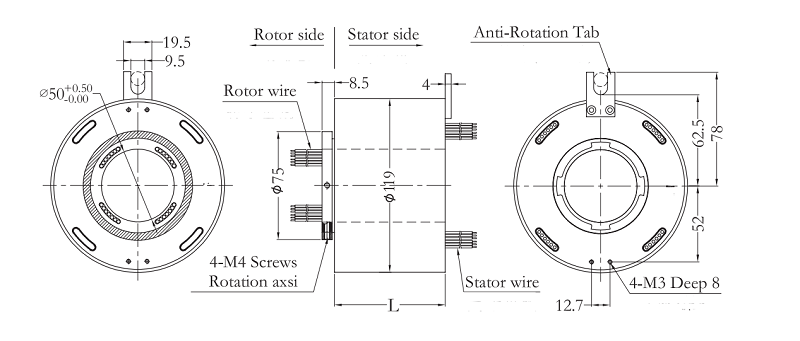

Through Bore Slip Ring XH50119 Series

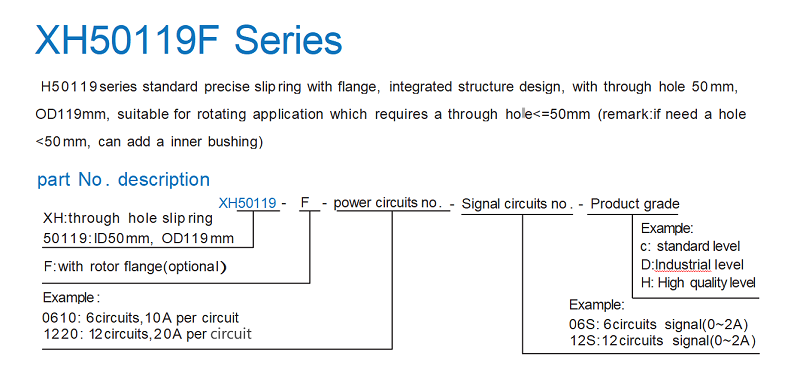

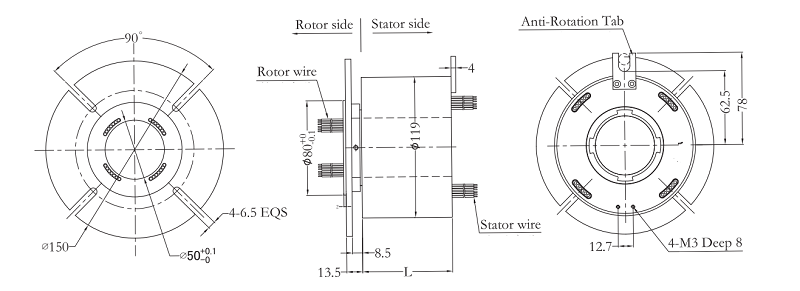

Through Bore Slip Ring XH50119F Series

Functions

Power Transmission:

Slip rings provide power transmission for rotating mechanical equipment, ensuring a continuous power supply during rotation.

Signal Transmission:

Slip rings transmit control signals and data signals between rotating and fixed equipment, ensuring the device operates normally and communicates effectively.

System Optimization:

The use of slip rings simplifies system structure, improves system performance, and prevents wires from twisting or being damaged during rotation.

Application Areas

Industrial Applications:

Slip rings are widely used in wind turbines, robotic arms, and industrial robots, providing power and signal transmission for these devices' rotating components.

Medical Equipment:

In medical equipment, slip rings are used in CT scanners, MRI machines, and more, ensuring continuous power and signal transmission during rotation.

Aerospace:

Slip rings are essential in aerospace applications, such as helicopters and satellites, providing reliable power and signal transmission to rotating components.

Entertainment Facilities:

In amusement park rides, slip rings ensure continuous power and signal transmission during rotation, enhancing the safety and reliability of the rides.

Maintenance and Care

Maintenance and Care

Cleaning:

Regularly clean slip rings and wires with special cleaners and brushes to keep contact surfaces free of oil and dust. Allow slip rings and wires to air dry naturally after cleaning; avoid forced drying with hair dryers or similar devices.

Lubrication:

Regularly apply a suitable amount of lubricant to slip rings and brushes based on usage to reduce wear and friction. Choose lubricants according to the slip ring material and environment, avoiding incompatible lubricants.

Inspection:

Regularly check slip rings and brushes for wear, replacing severely worn parts as needed. Inspect the contact surfaces and wires for any damage or breaks, and promptly repair or replace damaged parts.

Storage:

When storing slip rings, keep them in a dry, well-ventilated, non-corrosive environment, avoiding prolonged exposure to high or low temperatures. Store slip rings and brushes separately to prevent them from pressing against or colliding with each other.

Precautions

Installation:

Follow product manuals and installation diagrams for proper and secure installation. During installation, protect the contact surfaces and wires from damage or contamination.

Usage:

Perform performance testing on slip rings before use to ensure they function correctly. During use, monitor the slip ring’s operational state, promptly identifying and addressing any abnormal conditions.

Replacement:

Replace worn slip rings or brushes in a timely manner to avoid impacting equipment performance. Choose compatible, high-quality replacement parts for best results.

Safety:

Follow safe operation guidelines when handling slip rings to avoid electric shock or injury. Disconnect power before replacing or servicing slip rings to ensure safety.

Maintenance Cycle:

Determine the maintenance cycle based on equipment usage and environmental conditions, with general checks and maintenance recommended every six months to a year. In harsh environments, shorten the maintenance cycle to ensure reliability and safety.