Rotary Slip Ring, also known as rotating Slip Ring or rotating conductive ring, is an important device that can transmit electrical signals and power during rotation. The following is a detailed introduction to its characteristics, functions, application areas, maintenance, and precautions.

Rotary Slip Ring, also known as rotating Slip Ring or rotating conductive ring, is an important device that can transmit electrical signals and power during rotation. The following is a detailed introduction to its characteristics, functions, application areas, maintenance, and precautions.

Definition of Rotary Slip Ring

Rotary Slip Ring, literally meaning "rotating slip ring", is a device designed to transmit electrical signals and power between rotating and fixed components. It usually consists of a rotating ring and one or more fixed rings, which are electrically connected through sliding contact.

Characteristics

Rotary slip ring allows for the transmission of electrical signals and power during rotation without interrupting the rotation.

High reliability: Using high-quality materials and precision manufacturing processes to ensure long-term stable operation.

Multiple transmission methods: Supports the transmission of analog signals, digital signals, and power.

Customized design: Customized design can be provided according to customer needs, including size, number of transmission channels, etc.

Function

Signal transmission: Rotary slip rings can transmit various electrical signals such as audio, video, data, etc. during the rotation process.

Power transmission: In addition to signal transmission, it can also transmit electricity to provide the required electrical energy for rotating components.

Contactless transmission: In some advanced designs, the Rotary slip ring adopts a contactless transmission method, avoiding the wear and noise caused by traditional sliding contact.

Parameter Drawings

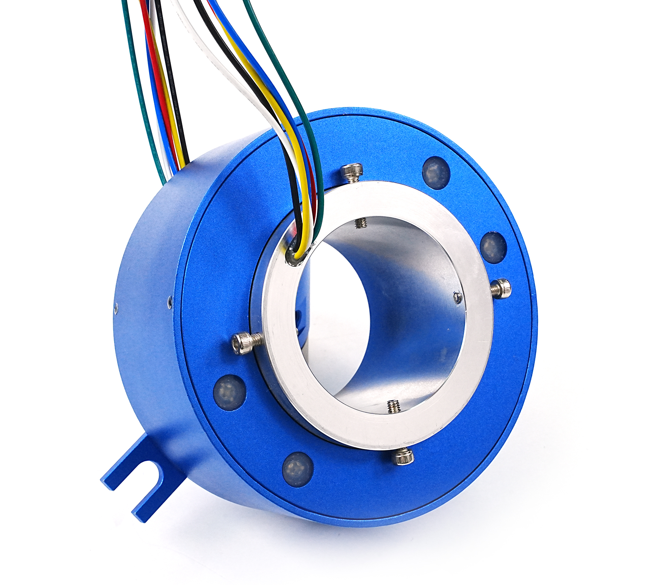

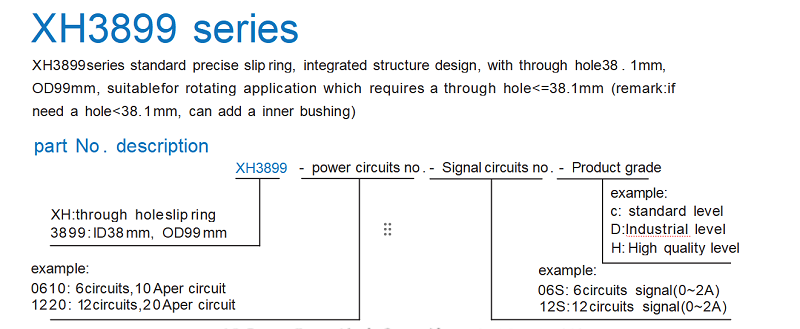

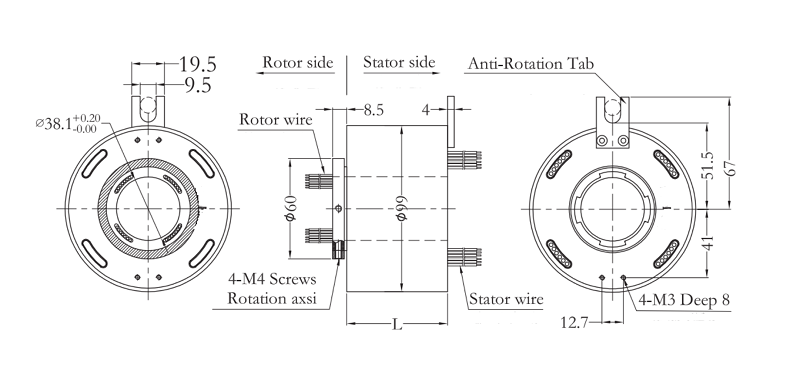

Through Bore Slip Ring XH3899 Series

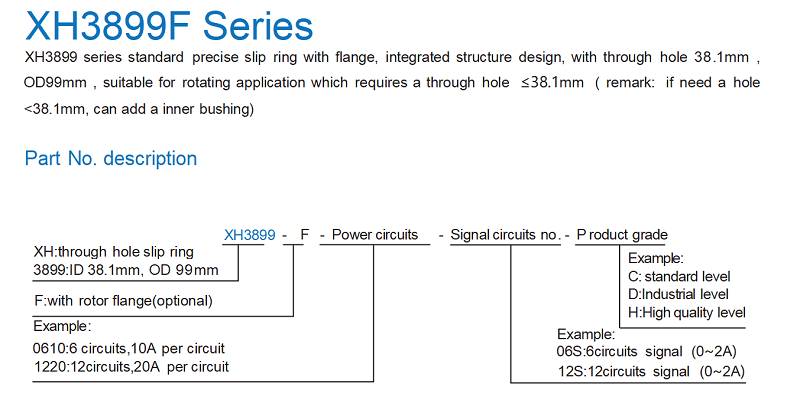

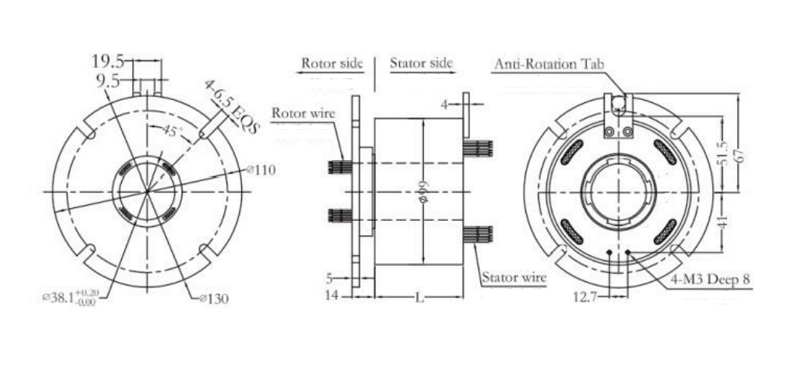

Through Bore Slip Ring XH3899F Series

Application Fields

Aerospace: In the aerospace field, Rotary slip rings are widely used for signal and power transmission of various rotating components, such as radar antennas, gyroscopes, etc.

Military equipment: Rotary slip rings are used in military equipment to transmit signals and power from systems such as radar and communication, ensuring that the equipment can still function properly during rotation.

Industrial equipment: Rotary slip rings are used in industrial equipment to transmit signals and power from various sensors, controllers, and other devices, such as wind turbines, industrial robots, etc.

Medical equipment: In medical equipment, Rotary slip rings are used to transmit signals and power from CT, MRI, and other devices to ensure stable operation during rotation.

Maintenance and upkeep

Regular inspection: Regularly inspect the Rotary slip ring, including appearance, contact surfaces, transmission channels, etc., to ensure that there is no damage or wear.

Cleaning and maintenance: Use a suitable cleaning agent to clean the Rotary slip ring, remove surface dirt and grease, and keep the contact surface clean and smooth.

Lubrication treatment: For Rotary slip rings that require lubrication, an appropriate amount of lubricant should be added regularly to reduce wear and noise.

Avoid overload: During use, the Rotary slip ring should be protected from excessive current or voltage to prevent damage to the equipment.

Prevent moisture: Keep the Rotary slip ring dry to avoid corrosion and damage to the equipment caused by humid environments.

Precautions

Installation requirements: When installing the Rotary slip ring, it should be ensured that the gap between it and the rotating and fixed components is appropriate to avoid wear or damage caused by being too tight or too loose.

Transmission limitations: When using Rotary slip rings to transmit signals and power, attention should be paid to their transmission limitations to avoid exceeding their design capabilities and causing equipment damage.

Temperature control: Rotary slip rings generate a certain amount of heat during operation. It is important to ensure that the working environment temperature is moderate to avoid adverse effects on the equipment caused by excessively high or low temperatures.

Protective measures: When using Rotary slip rings in harsh environments, corresponding protective measures should be taken, such as dust and water prevention, to ensure the normal operation of the equipment.

Repair and replacement: Once a malfunction or damage is found in the Rotary slip ring, timely repair or replacement should be carried out to avoid affecting the normal operation of the equipment.

Case analysis

Taking wind turbines as an example, the blades of wind turbines need to transmit various signals and electricity during the rotation process to achieve monitoring and control of the blades. Rotary slip rings are widely used in the blade transmission system of wind turbines, achieving signal and power transmission during blade rotation. During use, regularly inspect, clean, and lubricate the Rotary slip ring to ensure its normal operation. At the same time, be careful to avoid adverse effects on equipment caused by overload and humid environments.

In summary, the Rotary slip ring, as an important rotary transmission device, plays a significant role in fields such as aerospace, military equipment, industrial equipment, and medical equipment. During use, regular maintenance and upkeep should be carried out to ensure its normal operation and extend its service life. At the same time, pay attention to following relevant precautions and protective measures to ensure the safety and reliability of the equipment.