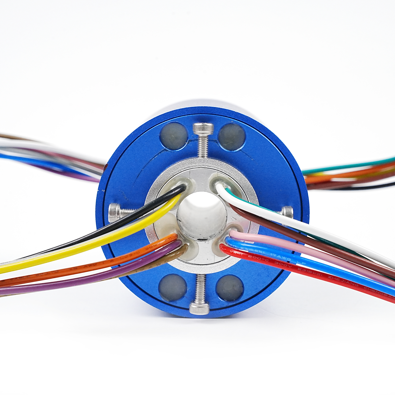

Definition

An Electrical Slip Ring, also known as an electric slip ring, is a rotary joint device used for transmitting electricity or signals. It allows power to be transmitted from stationary structures to rotating structures, or signals and data to be transmitted from fixed ends to rotating ends, while maintaining continuous rotation of equipment or systems.

Characteristics

Electrical performance: Electric slip rings have standard specifications for electrical parameters such as rated voltage, rated current, insulation resistance, and contact resistance, ensuring the stability and reliability of their electrical connections.

Environmental adaptability: Electric slip rings can adapt to different usage environments, such as high temperature, low temperature, humidity, etc., ensuring their reliability and safety under various harsh conditions.

Structure and installation: Electric slip rings have various structural designs and installation methods, such as composite carbon brushes, single fiber brushes, and multi fiber brushes, to meet the needs of different application scenarios.

Signal transmission: Electric slip rings can accurately transmit various signals such as Ethernet, USB, RS, Canbus, FireWire, as well as servo motor signals, encoder signals, strain gauge signals, thermocouples, etc.

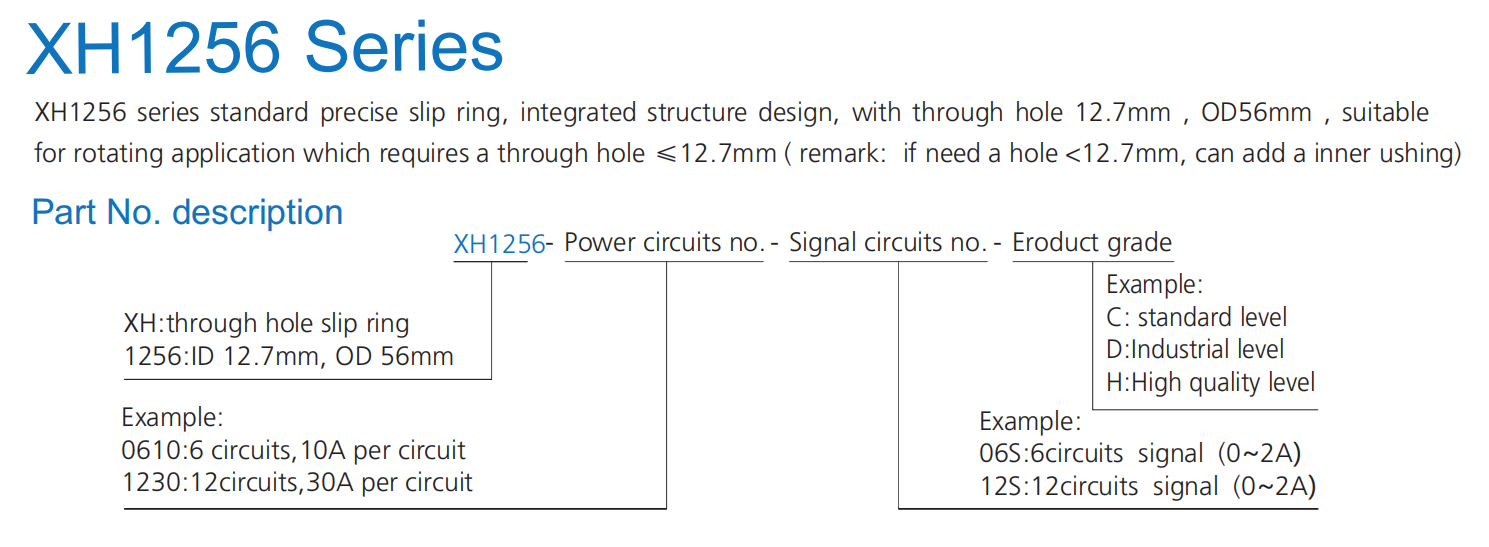

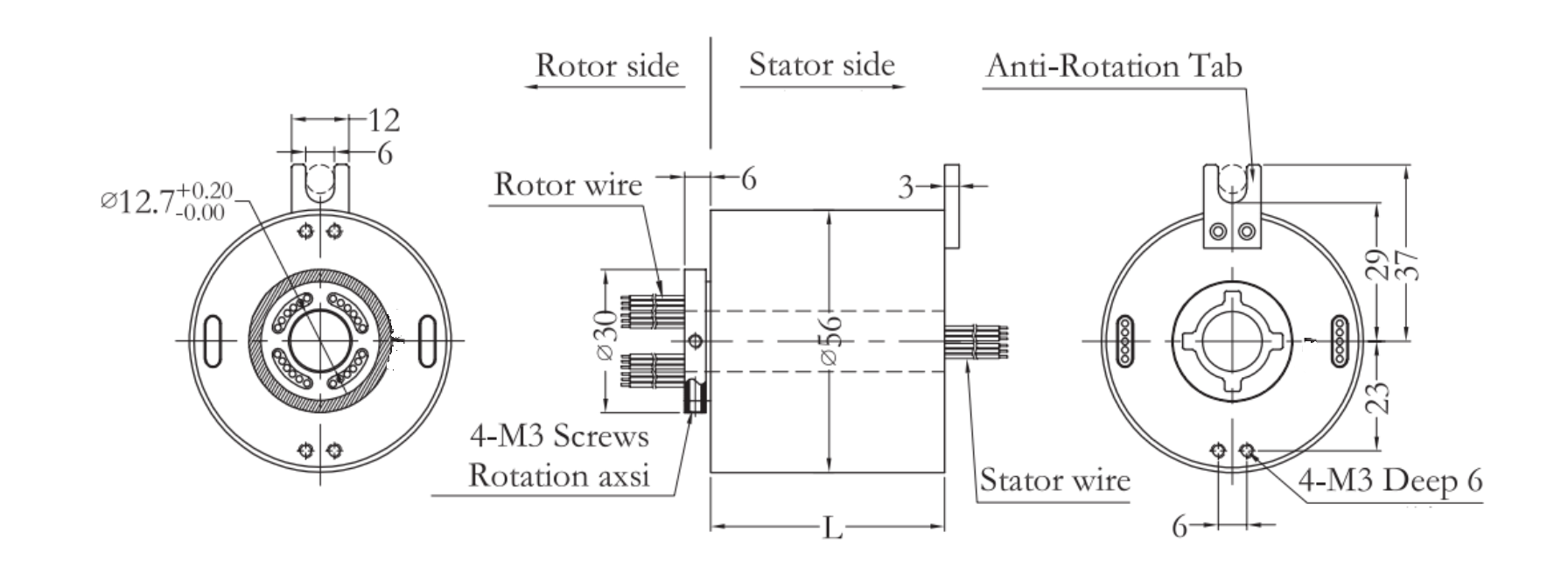

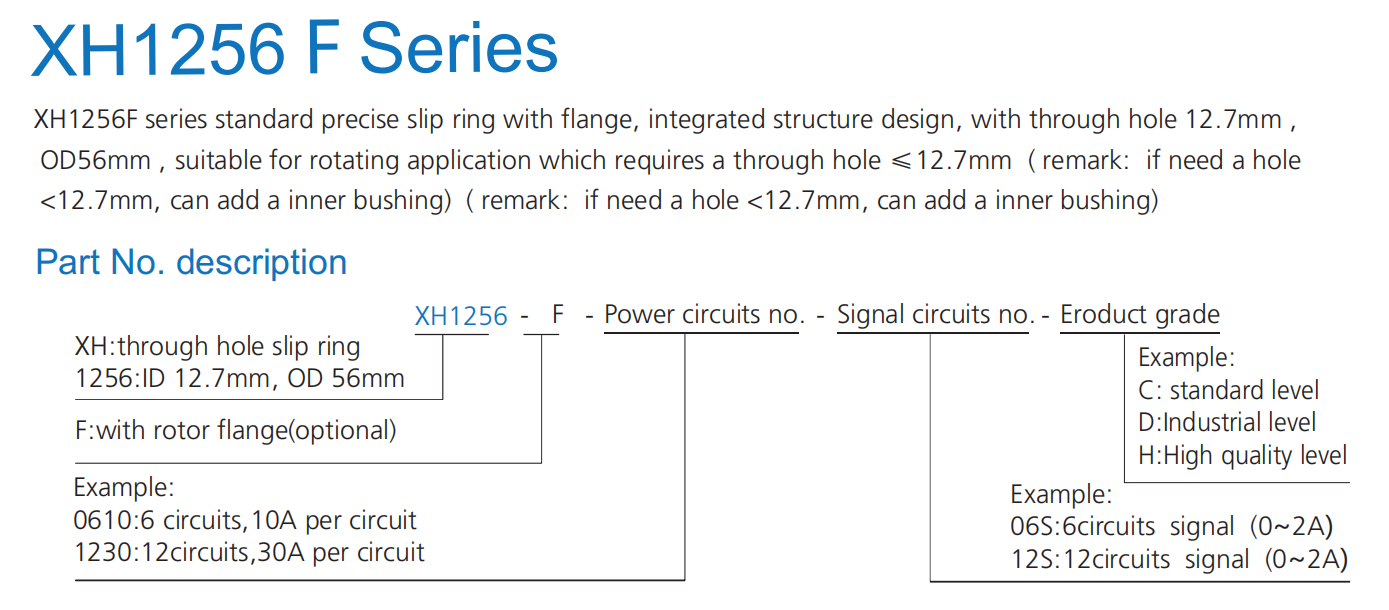

Parameter Drawings

Function

Circuit connection: The main function of an electric slip ring is to serve as a circuit connection device, transmitting power, signals, or data from the fixed end to the rotating end, ensuring the normal operation of rotating equipment or systems.

Preventing wire entanglement: In rotating equipment, wires are prone to entanglement or breakage due to rotation, and slip rings enable the transmission of wires in rotating equipment through physical contact, avoiding the problem of wire entanglement and breakage.

Signal transmission: Electric slip rings can transmit various signals, including control signals, data signals, etc., to achieve information exchange between rotating equipment or systems.

Application Fields

Application Fields

Electric slip rings are widely used in various devices or systems that require rotation, such as:

Wind turbine: The rotating blades in wind turbines need to transmit power and signals to fixed parts through slip rings to achieve control and monitoring of wind power generation.

Rotating platform: Rotating platforms are commonly used in exhibitions, performances, and other occasions, requiring the transmission of power and signals to the rotating platform through slip rings to control the lighting, sound, and other equipment on the platform.

Camera gimbal: The camera gimbal needs to achieve 360 degree rotation for shooting, and the electric slip ring is used to transmit power and signals to the camera on the gimbal for camera control and data transmission.

CT scanner: The rotating part of the CT scanner needs to transmit power and signals to the fixed part through an electric slip ring to achieve control and data acquisition of CT scanning.

Industrial machinery: In industrial machinery such as plastic molding machines, centrifugal machines, winding machines, etc., slip rings are used to transmit power and signals to rotating parts to achieve mechanical control and operation.

Maintenance and upkeep

In order to ensure the normal operation and extend the service life of the slip ring, regular maintenance and upkeep are required, including:

Regular inspection: Regularly check whether the electrical connection of the slip ring is firm, whether the contact is good, and whether there are signs of wear or damage.

Cleaning and lubrication: Regularly clean the contact surface and surrounding environment of the electric slip ring, remove impurities such as dust and oil, and apply an appropriate amount of lubricating grease to reduce friction and wear on the contact surface.

Replace worn parts: If the contact surface of the electric slip ring, electric brush, and other components are found to be severely worn, they should be replaced in a timely manner to ensure the stability and reliability of the electrical connection.

Electrical testing: Regularly conduct electrical tests on the slip ring, such as insulation resistance testing, contact resistance testing, etc., to ensure that its electrical performance meets the specified requirements.

Precautions

When using electric slip rings, the following precautions should be taken:

Installation requirements: The installation of the electric slip ring should comply with the specified requirements, including installation position, installation method, fixing method, etc., to ensure its normal operation and safety.

Working environment: Electric slip rings should adapt to different working environments, such as temperature, humidity, vibration, etc., and avoid using them in harsh environments to avoid affecting their performance and lifespan.

Electrical parameters: When selecting and using slip rings, attention should be paid to whether their electrical parameters meet application requirements, such as rated voltage, rated current, etc., to ensure the stability and reliability of electrical connections.

Maintenance: Regularly maintain the electric slip ring, including cleaning, lubricating, replacing worn parts, etc., to extend its service life and ensure normal operation.

Operation specifications: When operating the electric slip ring, the operation specifications should be followed to avoid equipment damage or personnel injury caused by improper or erroneous operation.

Safety protection: When using electric slip rings, attention should be paid to safety protection, such as wearing insulated gloves, using insulated tools, etc., to prevent the occurrence of safety accidents such as electric shock or short circuit.