Collector Rings typically consist of an assembly of individual conducting segments that are interconnected to form a continuous path for electrical current. These conducting segments are mounted on a circular or annular frame, which allows them to rotate while maintaining electrical contact.

The individual conducting segments themselves are made of high-conductivity materials, such as copper or silver, that efficiently transmit electrical current. As the collector ring rotates, the segments make contact with brushes or wiper contacts, which are stationary and connected to the power source. This contact allows for the transfer of electrical power or signals to and from the rotating components.

One of the key advantages of Collector Rings is their ability to transmit electrical current reliably in rotating applications. They are commonly used in electrical machines, such as generators, motors, and alternators, where power needs to be transferred between stationary and rotating parts. The design of the collector ring ensures that electrical contact is maintained even as the ring rotates, minimizing wear and tear and maximizing efficiency.

Collector rings have various applications, including automotive systems, industrial machinery, and aerospace technology. In automotive systems, they are often used in alternators and starters to transfer power from the engine to the electrical system. In industrial machinery, they may be found in electric motors and generators, enabling the conversion of mechanical energy to electrical energy and vice versa. In aerospace technology, collector rings play a crucial role in transmitting power and signals to rotating components, such as gyroscopes and sensors.

Parameter Drawings

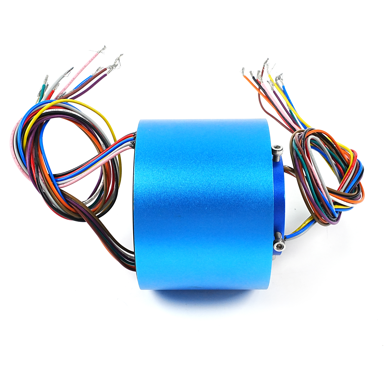

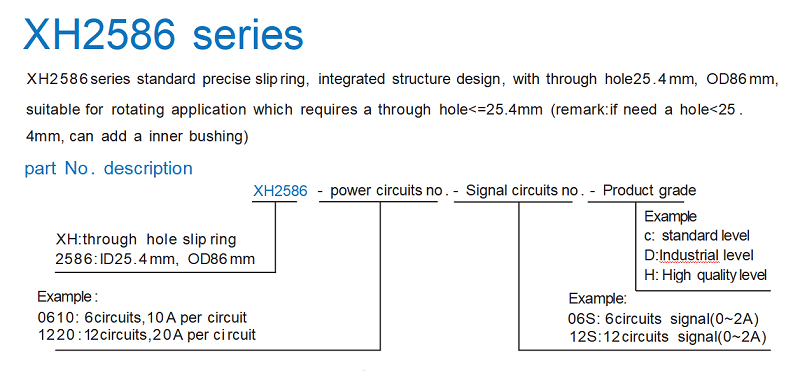

Through Bore Slip Ring XH2586 Series

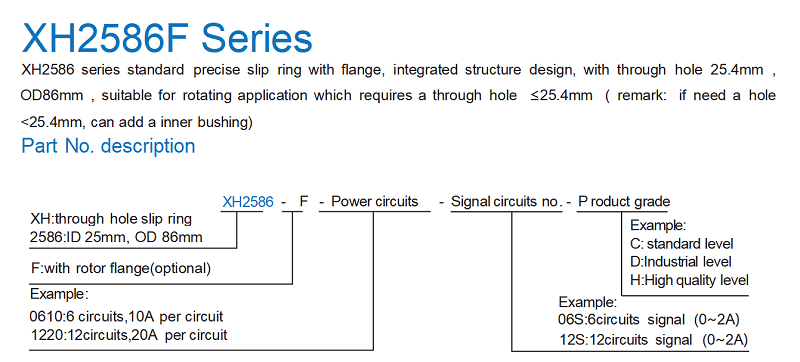

Through Bore Slip Ring XH2586F Series

Collector Ring Assembly

The Collector Ring Assembly is a precision-engineered component that ensures reliable electrical contact in rotating applications. It consists of a circular frame and multiple conducting segments, which are precisely positioned and secured to maintain electrical continuity. The assembly is designed to withstand high speeds and temperatures, ensuring consistent performance and longevity.

Collector Ring for Motors

The Collector Ring for Motors is a specialized component that enables the transfer of electrical power to the rotor of an electric motor. It is typically made of high-conductivity materials and is designed to withstand the mechanical and electrical stresses associated with motor operation. This collector ring ensures that the rotor receives the necessary power to function efficiently, even at high speeds.

Collector Ring for Generators

The Collector Ring for Generators serves a similar function, transmitting electrical power from the rotor to the stator in a generator. It is crucial for the conversion of mechanical energy to electrical energy and is designed to handle the high currents and voltages generated by the generator. This collector ring ensures that the generated power is efficiently transferred to the electrical grid or other loads.

Industrial Collector Rings

Industrial Collector Rings are designed for use in harsh environments and demanding applications. They are made of durable materials and are engineered to withstand extreme temperatures, pressures, and vibrations. These collector rings are commonly used in industrial machinery, such as cranes, elevators, and conveyor systems, where reliable electrical contact is essential for safe and efficient operation.

Automotive Collector Rings

Automotive Collector Rings are specifically engineered for use in automotive systems, such as alternators and starters. They are designed to withstand the high temperatures and vibrations associated with automotive engines and are made of materials that can resist corrosion and wear. These collector rings ensure that the electrical system of a vehicle functions reliably, even under extreme conditions.