2025-03-26 16:16:34

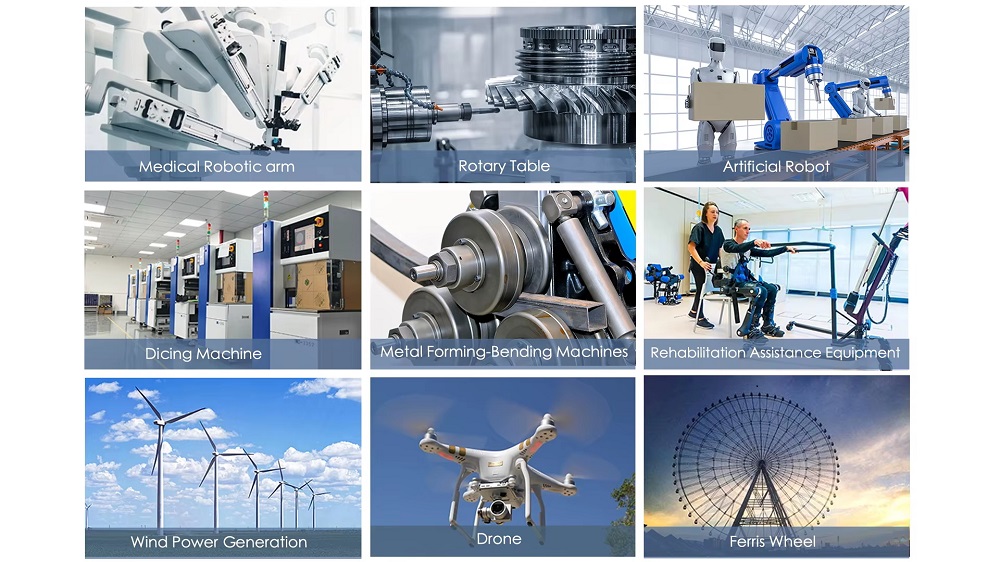

Slip Rings are essential components in various industrial applications, enabling the seamless transmission of electrical power and signals between rotating and stationary parts. They are widely used in industries where continuous rotation and power/data transfer are required.

What Are Slip Rings and How Do They Work?

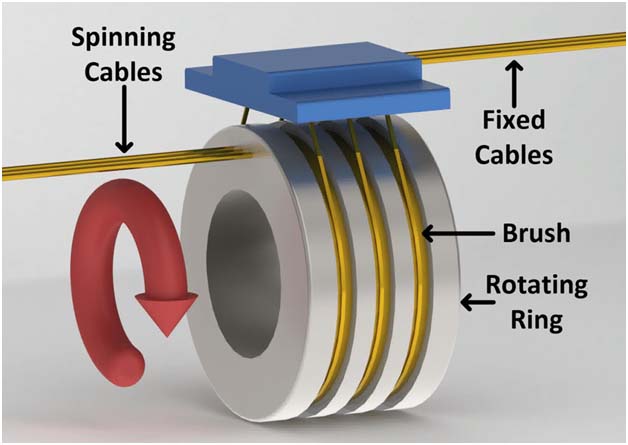

A Slip Ring is an electromechanical device that allows the transmission of electrical power and signals from a stationary structure to a rotating component. They are widely used in industries such as wind energy, medical imaging, and robotics, where continuous rotation is required.

How Do Slip Rings Work?

A slip ring consists of three main components:

A slip ring consists of three main components:

Rotating Ring – Conducts electricity while spinning.

Stationary Brush – Maintains electrical contact with the ring.

Housing – Protects internal components from dust, moisture, and wear.

When power or data is applied to the brushes, it transfers through the rings, enabling uninterrupted 360-degree rotation while maintaining electrical connectivity.

Technical Specifications & Performance Data

Voltage Capacity: Typically ranges from 12V to 6000V, depending on industrial use.

Current Rating: Can handle anywhere from 1A to 1000A based on application needs.

Rotational Speed: Standard models operate at 250-500 RPM, while high-speed slip rings can reach 10,000 RPM (e.g., in CT scanners).

Lifespan: High-quality slip rings last between 10 million to 100 million rotations, depending on materials and environmental conditions.

These features make slip rings crucial for ensuring efficient power transmission, reduced wear, and improved system reliability in industrial applications.

Top 10 Industrial Applications of Slip Rings

1. Wind Turbines

Wind turbines require slip rings to transfer electrical signals and power from the rotating blades to the stationary grid system. These slip rings ensure continuous energy production and facilitate pitch control, which adjusts the blade angles for optimal energy efficiency.

2. CCTV Surveillance Systems

In CCTV cameras,slip rings allow 360-degree rotation of the camera’s pan-tilt system while maintaining a stable electrical connection. This ensures uninterrupted power supply and data transmission, which is crucial for real-time surveillance and security applications.

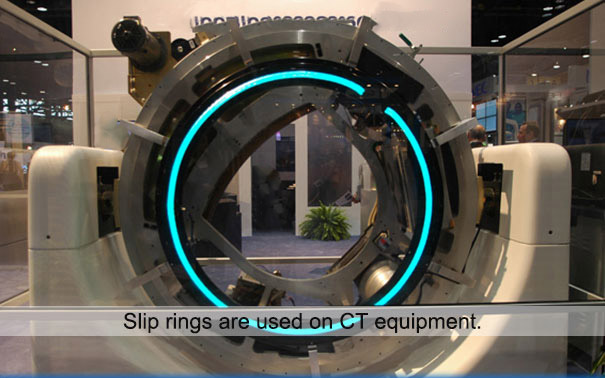

3. Medical Equipment (CT Scanners & MRI Machines)

Slip rings play a vital role in medical imaging devices like CT scanners and MRI machines, where high-speed rotation is necessary to capture detailed internal images of the human body. They allow continuous power and data transfer between rotating and stationary components without causing signal interference.

4. Robotics & Automation

In robotics and industrial automation,slip rings are used to provide uninterrupted electrical connections for robotic arms and automated assembly lines. This enables smooth rotation and precise movement, improving manufacturing efficiency and reducing downtime.

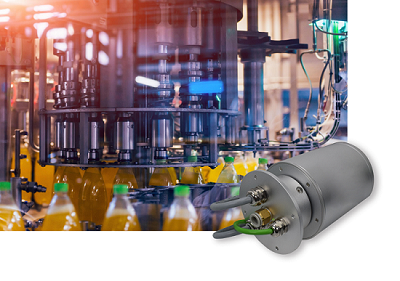

5. Rotary Packaging Machinery

Slip rings are widely used in automated packaging systems, where they help maintain uninterrupted operation in rotating filling machines, labeling systems, and capping machines. They ensure consistent performance in high-speed production environments.

6. Aerospace & Defense Systems

In military and aerospace applications, slip rings are used in radar systems, missile launchers, and aircraft control systems. They allow continuous rotation and secure data transmission, which is crucial for communication and targeting systems in defense technology.

7. Oil & Gas Industry

The oil and gas sector relies on slip rings for drilling rigs and offshore platforms. These devices allow power and data transfer in rotary drilling equipment, ensuring reliable operations in harsh environments where durability is critical.

8. Maritime & Underwater Applications

Slip rings are used in marine vessels, underwater ROVs (Remotely Operated Vehicles), and sonar systems to facilitate smooth power transmission in rotating parts. They help in underwater exploration, offshore energy production, and naval defense systems.

9. Radar & Communication Systems

Radar antennas require continuous rotation for scanning and tracking targets. Slip rings ensure a stable electrical connection, allowing uninterrupted data flow for air traffic control, weather monitoring, and military surveillance.

10. Industrial Machinery & Heavy Equipment

Many heavy-duty machines in construction, mining, and manufacturing use slip rings to transfer power and signals in rotating mechanisms. They improve machine efficiency and reduce wear and tear caused by excessive wire twisting.

Slip rings are critical in various industrial applications, enabling smooth and efficient operations in machines requiring continuous rotation. From wind turbines and medical imaging to robotics and radar systems, their role is indispensable in modern industry.

If you're looking for high-quality slip rings for your specific industrial needs, feel free to contact us for expert advice and solutions.