2025-03-08 18:52:23

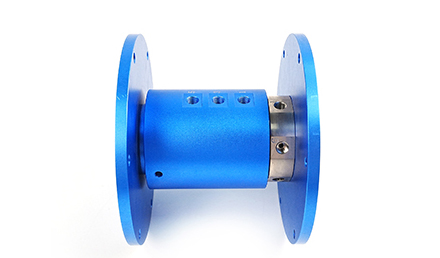

In the application scenario of multi-channel Fluid Slip Ring, achieving precise flow control and independent transmission of each channel, and effectively preventing mutual interference, is the key to ensuring efficient and stable operation of the system.

Structural Design Optimization

Independent Channel Layout: In the structural design of the multi-channel Fluid Slip Ring, it is necessary to physically isolate each channel. By adopting a multi-layer concentric cylindrical structure or modular design, each channel has an independent flow channel space, avoiding physical contact between different fluids during transmission. For example, in some high-precision industrial equipment, precise mechanical processing techniques are used to etch the flow channels of each channel onto an insulating and corrosion-resistant material substrate, fundamentally eliminating cross contamination and mutual interference between channels.

Optimizing Channel Shape: Reasonable design of channel shape and size is crucial for flow control. According to the characteristics and flow requirements of different fluids, a streamlined flow channel design is adopted to reduce the resistance and turbulence of fluids during transmission. For example, for high viscosity fluids, increasing the channel diameter appropriately and using smooth inner wall treatment can reduce the flow resistance of the fluid and ensure stable flow rate. At the same time, through computational fluid dynamics (CFD) simulation analysis, the fluid flow under different channel shapes is predicted and optimized, further improving the accuracy of flow control.

Flow Control Technology

Flow Sensors and Feedback Control: Install high-precision flow sensors in each channel to monitor real-time fluid flow data. The sensor feeds back the collected flow signal to the control system, which analyzes and compares it based on the preset flow value, and then precisely controls the flow by adjusting the opening of the flow regulating valve. This closed-loop control method can quickly respond to changes in flow rate, adjust control parameters in a timely manner, and ensure that the flow rate always remains within the set accuracy range. For example, in the chemical production process, this feedback control technology can accurately control the flow ratio of different chemical raw materials, ensuring the stability of the production process and product quality.

Intelligent Control Algorithm: Advanced intelligent control algorithms such as proportional integral derivative (PID) control algorithm, fuzzy control algorithm, etc. are adopted to further improve the accuracy and dynamic response performance of flow control. The PID control algorithm adjusts the flow control valve by performing proportional, integral, and derivative operations on the flow deviation, and outputting appropriate control signals. Fuzzy control algorithms mimic human thinking and intelligently adjust traffic based on the trend of traffic changes and fuzzy rule libraries. These intelligent control algorithms can adapt to complex and changing working conditions, effectively improving the accuracy and reliability of flow control.

Sealing and Isolation Technology

High Performance Sealing Materials: Choosing appropriate sealing materials is an important guarantee to prevent mutual interference between channels. For different types of fluids, materials with good corrosion resistance, wear resistance, and sealing performance are used. For example, for corrosive fluids, corrosion-resistant sealing materials such as polytetrafluoroethylene (PTFE) are selected; For fluid transmission in high-temperature and high-pressure environments, metal seals or high-performance rubber seals are used. At the same time, by optimizing the sealing structure design, such as using multiple seals, lip seals, etc., the reliability of the seal is improved to prevent fluid leakage and channeling between channels.

Electromagnetic Shielding and Isolation: In some multi-channel Fluid Slip Rings involving electrical signal transmission, the impact of electromagnetic interference on flow control and signal transmission also needs to be considered. By using electromagnetic shielding materials to shield each channel, the coupling and interference of electromagnetic signals between channels are reduced. At the same time, reasonable layout and isolation of electrical signal transmission lines should be carried out to avoid mutual influence between electrical signals and fluid transmission channels, ensuring that each channel can work independently and stably.

By optimizing structural design, adopting advanced flow control technology, and reliable sealing and isolation technology, multi-channel Fluid Slip Ring can achieve precise flow control and independent transmission of each channel, effectively preventing mutual interference and meeting the high-precision fluid transmission needs of different industrial fields.