2025-02-22 18:04:49

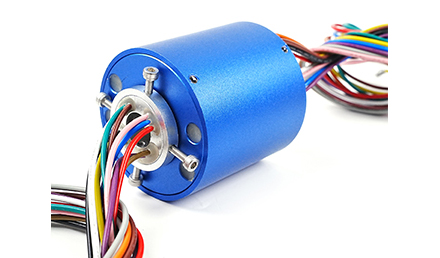

Custom Slip Rings, as important electromechanical components, are widely used in various devices that require the rotation to transmit signals and energy. To ensure that Custom Slip Rings maintain good performance and stability during long - term use, after - sales maintenance is of great significance. The following will detail the precautions for the after - sales maintenance of Custom Slip Rings.

Daily Inspection

Appearance Inspection: Regularly check the appearance of the Custom Slip Rings to see if there are any cases of shell damage, deformation, or corrosion. If problems are found with the shell, it may cause the internal components to be exposed, thus being affected by external factors such as dust and moisture, reducing the performance of the Custom Slip Rings.

Inspection of Connection Parts: Carefully check the connection parts between the Custom Slip Rings and other components of the device to ensure that the connections are firm and there are no signs of loosening or falling off. Loose connections may lead to unstable signal transmission or interruption of energy transmission.

Cleaning and Maintenance

Cleaning Frequency: Determine a reasonable cleaning cycle based on the operating environment and frequency of the Custom Slip Rings. Generally, in a dusty or harsh working environment, more frequent cleaning is required.

Cleaning Tools and Methods: Use a clean and soft brush or compressed air to remove dust and debris from the surface of the Custom Slip Rings. For stubborn stains, special cleaning agents can be used, but be careful that the cleaning agent does not corrode the materials of the Custom Slip Rings. Operate carefully during cleaning to avoid damaging the internal structure of the Custom Slip Rings.

Electrical Performance Testing

Resistance Measurement: Regularly use professional resistance measuring instruments to detect the contact resistance of the Custom Slip Rings. If the contact resistance increases abnormally, it may indicate poor contact between the brushes and the conductive rings of the Custom Slip Rings, and adjustments or replacements need to be made in a timely manner.

Insulation Performance Testing: Check the insulation performance of the Custom Slip Rings to ensure that the insulation resistance meets the specified standards. A decrease in insulation performance may lead to problems such as electric leakage or short - circuit, affecting the normal operation of the device.

Lubrication Maintenance

Lubricant Selection: Select a lubricant suitable for the operating environment and working conditions of the Custom Slip Rings. Different types of Custom Slip Rings may require different lubricants. For example, high - temperature - resistant lubricants are needed in high - temperature environments.

Lubrication Frequency and Method: Lubricate the Custom Slip Rings regularly according to the requirements of the product manual. When lubricating, ensure that the lubricant is evenly applied to the parts that need lubrication, and avoid over - lubrication or under - lubrication.

Fault Troubleshooting and Handling

Abnormal Signal Transmission: If there are problems such as unstable signal transmission or interruption in Custom Slip Rings, first check whether the connection lines are normal, and then check whether the brushes and conductive rings of the Custom Slip Rings are severely worn or dirty. If the brushes are worn, the brushes need to be replaced in a timely manner; if the conductive rings are dirty, clean them.

Abnormal Heating: If the Custom Slip Rings heat up abnormally during operation, it may be caused by excessive current, increased contact resistance, or poor lubrication. Check whether the electrical parameters meet the requirements and conduct a comprehensive inspection and maintenance of the Custom Slip Rings.

Storage Precautions

Environmental Requirements: If the Custom Slip Rings need to be stored temporarily, place them in a dry, ventilated environment free of corrosive gases. Avoid direct sunlight and high - temperature environments to prevent the aging of the Custom Slip Rings' materials and the decline of performance.

Packaging Protection: When storing, ensure that the Custom Slip Rings have good packaging protection to prevent them from being damaged by external forces.

In conclusion, the after - sales maintenance of Custom Slip Rings requires meticulous work in many aspects. Through regular inspections, cleanings, maintenance, and fault troubleshooting, problems can be discovered and solved in a timely manner, the service life of the Custom Slip Rings can be extended, and the stable operation of the device can be ensured. When users perform after - sales maintenance, they should strictly follow the operation requirements of the product manual. If there are any questions or complex problems, they should contact the manufacturer of the Custom Slip Rings or professional technicians in a timely manner for guidance and assistance.