Definition

Hydraulic Pneumatic Rotary Joint, is a device that can transfer liquid or gas media (such as water, air, hydraulic oil, etc.) while rotating. It combines the advantages of hydraulic and pneumatic systems, ensuring stable transmission of media during rotation through precise internal sealing structures and flow channel design. It is widely used in various fluid transmission systems that require rotational motion.

Characteristics

Flexible rotation: Hydraulic and pneumatic rotary joints can rotate flexibly within a large rotation angle, meeting the needs of various complex working conditions.

Reliable sealing: Advanced sealing technology is adopted to ensure that the medium will not leak during rotation, ensuring the stability and safety of the system.

Efficient transmission: By optimizing the flow channel design, the resistance of the fluid during transmission is reduced, and the transmission efficiency is improved.

Strong adaptability: It can adapt to the transmission needs of different media, pressures, and temperatures, and is widely used in various industrial fields.

Easy maintenance: The structural design is reasonable, easy to disassemble and clean, reducing maintenance costs.

Function

Medium transmission: The main function of Hydraulic Pneumatic Rotary Joints is to transmit liquid or gas media, such as hydraulic oil, water, air, etc.

Rotating connection: Maintain the continuity of medium transmission during device rotation to ensure the normal operation of the system.

Pressure transmission: In hydraulic systems, rotary joints can transmit hydraulic pressure and achieve power transmission of equipment.

Temperature control: In systems that require cooling or heating, rotary joints can transmit cooling water or heating medium to achieve temperature control.

Application Fields

Construction machinery, such as excavators, cranes, concrete mixer trucks, etc., hydraulic and pneumatic rotary joints play a role in medium transmission in rotating components (such as rotating platforms, rotating arms).

Automation equipment: In automated production lines, rotary joints are used to connect rotating components and ensure stable transmission of liquid or gas media.

Shipbuilding: Hydraulic and pneumatic rotary joints are used to transmit hydraulic oil or cooling water in rotating components such as servos and propellers of ships.

Aerospace: In aircraft landing gear, rotating wings and other components, rotary joints are used to transmit hydraulic oil or air pressure, achieve power transmission and temperature control.

In other fields such as metallurgy, chemical industry, papermaking, food processing, etc., hydraulic and pneumatic rotary joints are also widely used in various fluid transmission systems that require rotational motion.

Maintenance and upkeep

Regular inspection: Regularly inspect the rotary joint, including appearance, sealing performance, and flow channel smoothness, to ensure that it is in good condition.

Cleaning and replacement: Regularly clean the rotary joint according to usage to remove internal impurities and dirt. For severely worn seals and flow channel components, they should be replaced in a timely manner.

Lubrication: Add an appropriate amount of lubricant to the parts that require lubrication to reduce friction and wear, and extend service life.

Pressure regulation: According to system requirements, adjust the working pressure of the rotary joint reasonably to avoid damage to the equipment caused by excessive or insufficient pressure.

Temperature control: Ensure that the working temperature of the rotary joint is within the specified range to avoid adverse effects on the equipment caused by excessively high or low temperatures.

Precautions

Installation: When installing the rotary joint, ensure its coaxiality with the connecting components to avoid leakage and damage caused by improper installation.

Media selection: Choose the appropriate media according to system requirements to avoid using media incompatible with the rotary joint, which may cause leakage or damage.

Pressure limit: During use, it should be ensured that the working pressure of the rotary joint does not exceed its rated pressure to avoid damage caused by excessive pressure.

Temperature range: Ensure that the working temperature of the rotary joint is within the specified range and avoid adverse effects caused by excessively high or low temperatures.

Maintenance cycle: Develop a reasonable maintenance cycle based on usage and equipment requirements to ensure the normal operation of the rotary joint.

Operator training: Train operators to understand the structure, performance, usage methods, and precautions of rotary joints, ensuring the safe operation of equipment.

Emergency plan: Develop emergency plans, including leak handling, equipment failure handling, etc., to ensure timely measures can be taken in case of emergencies and reduce losses.

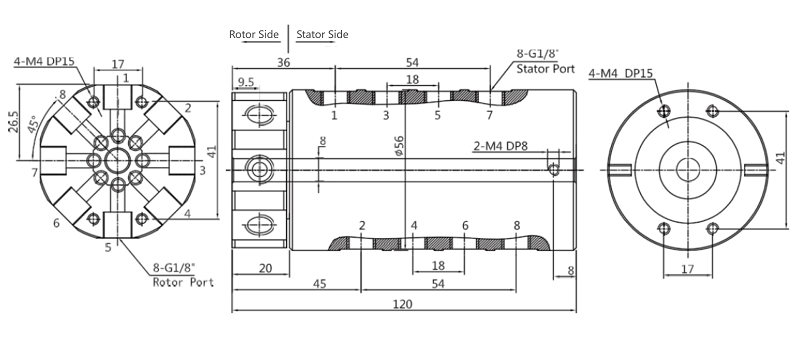

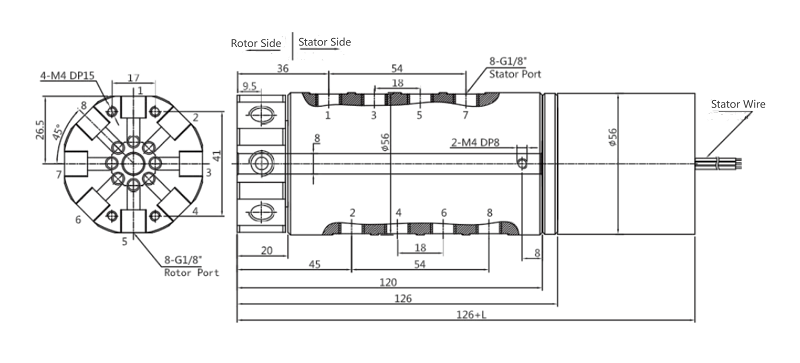

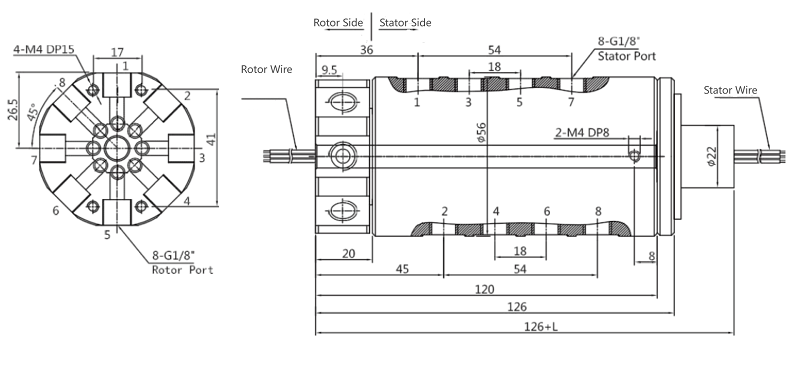

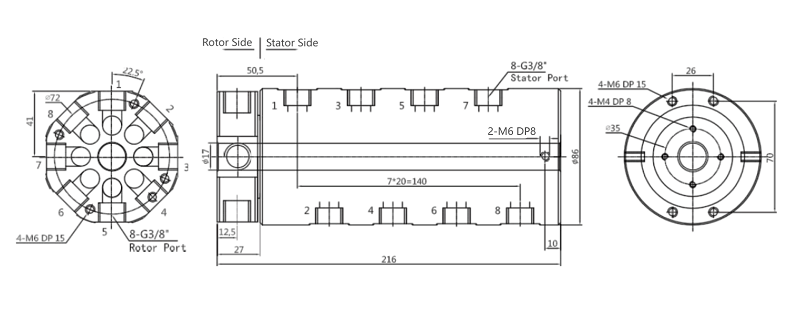

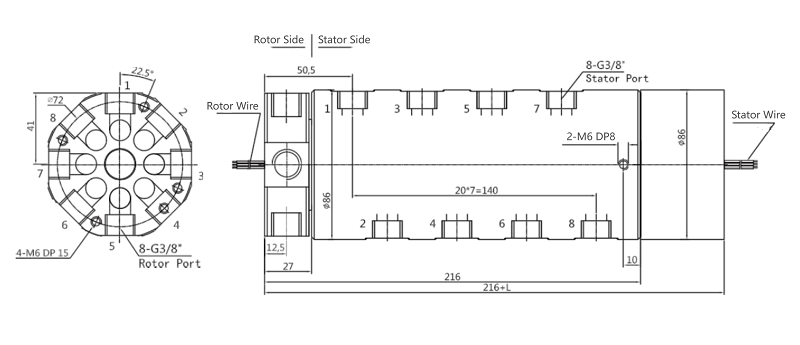

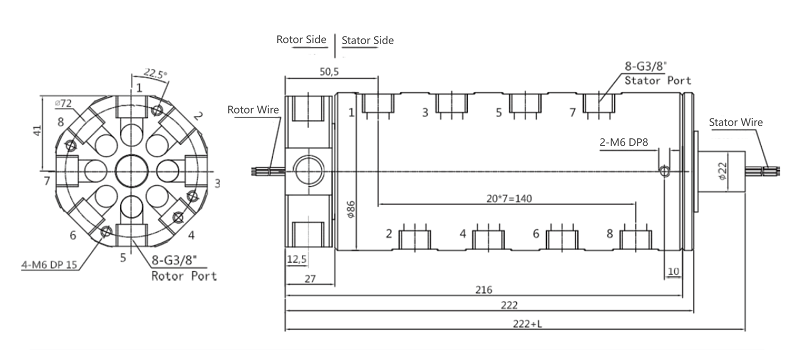

Parameter Drawings

Hydraulic Pneumatic Rotary Joint XQ08001

Hydraulic Pneumatic Rotary Joint XQ08003

The hydraulic pneumatic rotary joints are an important fluid transmission device, characterized by flexible rotation, reliable sealing, and efficient transmission. They are widely used in engineering machinery, automation equipment, shipbuilding, aerospace and other fields. During use, regular maintenance and upkeep should be carried out to ensure that it is in good condition. At the same time, attention should also be paid to the requirements of installation, medium selection, pressure limitation, temperature range, etc., to ensure the safe operation of the equipment.