Definition

Hybrid Slip Ring is a collector ring device. It is mainly used to transmit electrical signals and electrical energy between rotating parts and stationary parts, supporting continuous power supply and data transmission of equipment during rotation. Hybrid Slip Ring combines multiple transmission media, such as electricity, gas, liquid, etc., and can achieve efficient and stable signal and energy transmission in complex environments.

Features

Compact structure: The design of hybrid slip ring is usually very compact, which can save space and adapt to various compact equipment installation requirements.

Multi-media transmission: Supports hybrid transmission of multiple media such as electrical signals, gas circuits, liquid circuits, etc. to meet the needs of complex systems.

High performance: It has high insulation resistance, contact resistance and dielectric strength to ensure stable transmission of signals and energy.

Wear-resistant and durable: Made of wear-resistant materials, it can withstand long-term rotation and friction and extend service life.

Easy to maintain: The structural design is easy to clean and maintain, reducing maintenance costs.

Function

Continuous power supply: Provide continuous and stable power supply to the equipment during rotation to ensure the normal operation of the equipment.

Data transmission: supports the transmission of various data signals, including low-frequency, medium-frequency and high-frequency signals, suitable for different application scenarios.

Simplify system structure: By integrating multiple functions, reduce the number of system components, simplify the system structure, and improve system performance.

Safety protection: avoid twisting of wires during rotation and provide higher safety protection.

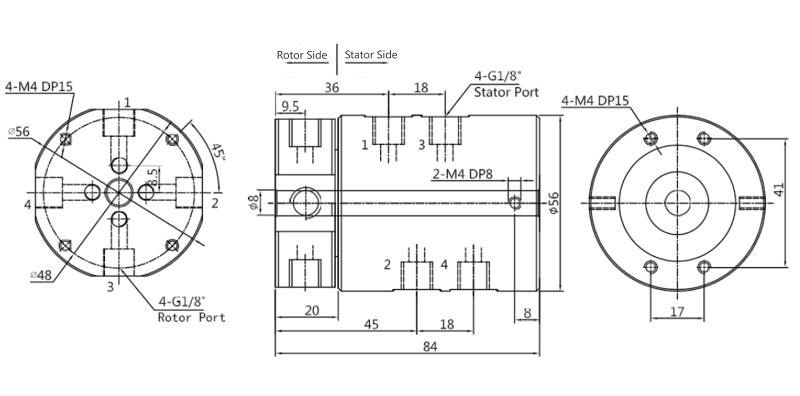

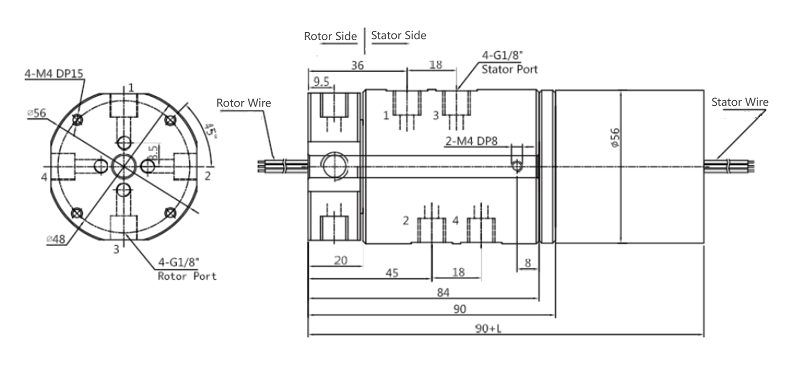

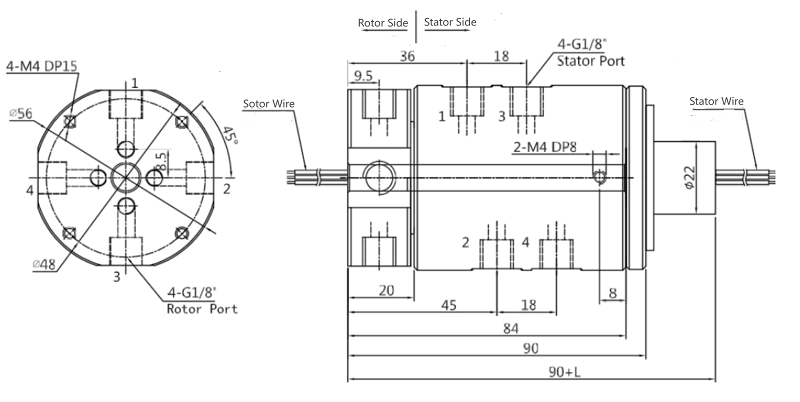

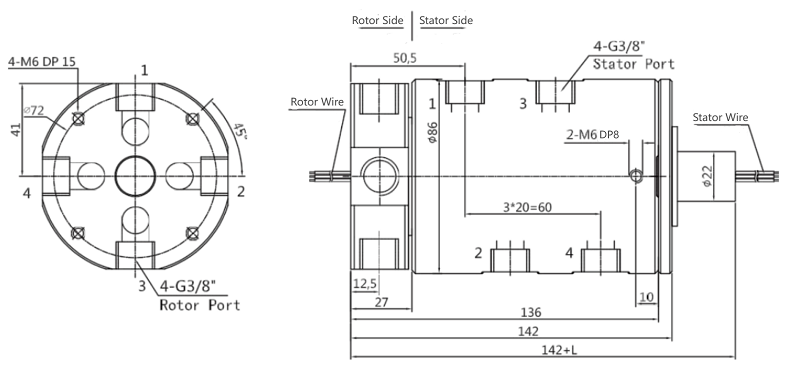

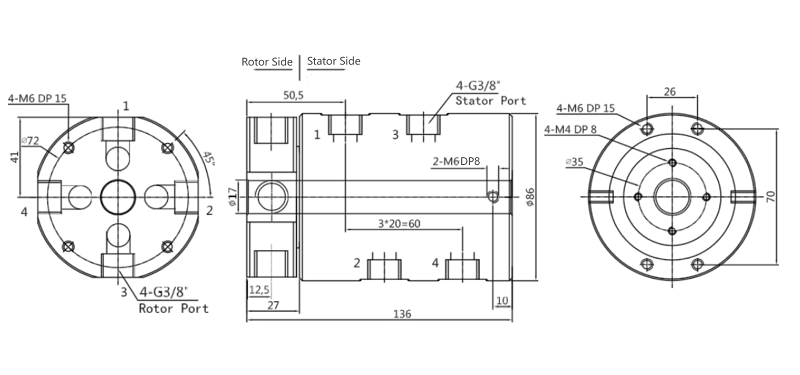

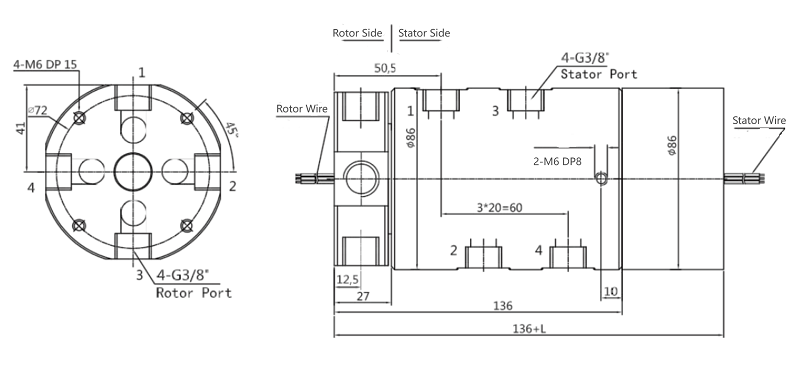

Parameter Drawings

Hydraulic Pneumatic Rotary Joint XQ04001

Hydraulic Pneumatic Rotary Joint XQ04003

Application field

Industrial automation: In automated production lines, hybrid slip rings are used to transmit control signals and power to achieve remote control and monitoring of equipment.

Aerospace: In aerospace equipment such as aircraft and satellites, hybrid slip rings are used to transmit radar signals, power, etc. to ensure the normal operation and communication of equipment.

Medical equipment: In medical equipment, hybrid slip rings are used to transmit image signals, power, etc., to support the rotation operation and image transmission of equipment.

Wind power generation: In wind power generation equipment, hybrid slip rings are used to transmit monitoring signals such as wind speed and wind direction and power to ensure the stable operation of equipment.

Amusement facilities: In amusement facilities, hybrid slip rings are used to transmit control signals and power to ensure the safe operation of facilities and the comfortable experience of passengers.

Maintenance and care

Maintenance and care

Regular inspection: Regularly check the performance indicators of the hybrid slip ring, such as contact resistance and insulation resistance, to ensure that they are within the normal range.

Cleaning and maintenance: Regularly clean the surface and interior of the hybrid slip ring to remove dust and dirt and keep it in good working condition.

Lubrication and maintenance: For hybrid slip rings that need lubrication, an appropriate amount of lubricant should be added regularly to reduce friction and wear.

Replacement of worn parts: For parts with severe wear, such as brushes, conductive rings, etc., they should be replaced in time to ensure the normal operation of the hybrid slip ring.

Avoid overload use: Avoid hybrid slip rings from running under overload or overload conditions to prevent them from being damaged or shortening their service life.

Precautions

Choose the appropriate model: According to the needs of the equipment and the working environment, select the appropriate hybrid slip ring model and specification to ensure that it can meet the transmission needs of the equipment.

Correct installation: Follow the installation instructions of the hybrid slip ring for correct installation to ensure that it matches the interface of the equipment and the connection is firm and reliable.

Avoid severe vibration: Avoid hybrid slip rings from running in an environment with severe vibration or shock to prevent them from being damaged or degraded in performance.

Pay attention to the temperature range: The operating temperature of the hybrid slip ring should be within the specified range to avoid damage caused by excessively high or low temperatures.

Prevent static interference: During the use of the hybrid slip ring, attention should be paid to preventing static interference to ensure stable signal transmission.

Regular calibration: For hybrid slip rings that need to accurately transmit data, calibration should be performed regularly to ensure its transmission accuracy and accuracy.

As an important transmission device, Hybrid Slip Ring has broad application prospects in industrial automation, aerospace, medical equipment, wind power generation, and amusement facilities. Through correct maintenance and compliance with precautions, the long-term stable operation of the hybrid slip ring can be ensured, providing strong support for the normal operation and performance improvement of the equipment.