Definition

Definition

Copper Slip Ring is a sliding electrical contact element made of copper material. It is usually designed as a circular structure containing conductive brushes or plates inside, which can maintain stable electrical signal transmission during rotation. Copper Slip Rings have been widely used in various fields due to their excellent conductivity, wear resistance, and corrosion resistance.

Characteristics

Excellent conductivity: Copper is a metal with excellent conductivity, therefore copper Slip Rings have outstanding performance in electrical signal transmission.

Strong wear resistance: Copper Slip Rings have undergone special processing and have high wear resistance, which can maintain stable performance during long-term use.

Corrosion resistance: Copper materials have good resistance to various corrosive media, allowing copper slip rings to maintain a long service life even in harsh environments.

Compact structure: The design of copper slip rings is usually very compact, occupying little space, and easy to integrate into various devices.

High reliability: Copper slip rings undergo rigorous testing and screening during the design and manufacturing process to ensure their high reliability in practical applications.

Function

Electrical signal transmission: The main function of copper slip rings is to transmit electrical signals, which can establish stable electrical connections between rotating and fixed components, achieving real-time data transmission.

Energy transfer: In addition to electrical signal transmission, copper slip rings can also be used to transfer energy, such as electricity or signal power.

Signal synchronization: In situations where signal synchronization is required, copper slip rings can ensure signal synchronization between rotating and fixed components, avoiding signal loss or delay.

Application Fields

Aerospace: In the aerospace field, copper slip rings are widely used in applications that require high-precision and high reliability electrical signal transmission, such as gyroscopes and flight control systems.

Military equipment: Radar systems, navigation systems, communication systems, etc. in military equipment require the use of copper slip rings to maintain electrical connections between rotating and fixed components.

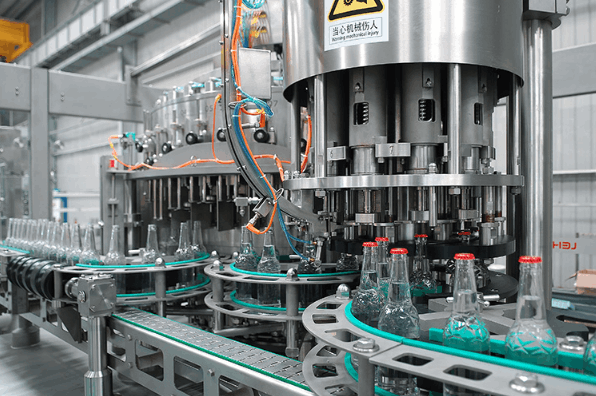

Industrial automation: In the field of industrial automation, copper slip rings are used in various rotating sensors, encoders, servo motors, and other equipment to achieve real-time signal transmission and energy transfer.

Medical equipment: Large medical devices such as CT machines and MRI machines also use copper slip rings to maintain electrical connections between rotating and fixed components, ensuring the normal operation of the equipment.

Transportation: In the field of transportation, copper slip rings are used in signal transmission systems for railway vehicles, communication systems for subway vehicles, and navigation systems for ships and airplanes.

Maintenance and upkeep

Regular inspection: Regularly inspect the copper slip ring to ensure that its surface is free of damage and corrosion, and check the wear of the conductive brush or conductive plate.

Cleaning and maintenance: Use a soft cloth or brush to gently wipe the surface of the copper slip ring to remove dust and dirt. Avoid using hard brushes or rough cleaning agents to prevent damage to the surface of the copper slip ring.

Lubrication treatment: Apply an appropriate amount of lubricant on the sliding contact surface of the copper slip ring to reduce friction and wear, and improve its service life.

Avoid moisture: Copper slip rings should be stored in a dry and ventilated environment, avoiding prolonged exposure to moisture to prevent corrosion.

Avoid high temperature: Avoid exposing copper slip rings to high temperature environments to prevent material deformation or performance degradation.

Precautions

Installation precautions: When installing copper slip rings, ensure that they fit well with rotating and fixed components to avoid situations of being too tight or too loose. At the same time, it should be ensured that the contact area between the conductive brush or conductive plate of the copper slip ring and the rotating parts is large enough to ensure good electrical signal transmission effect.

Precautions for use: During use, excessive force or torque should be avoided on the copper slip ring to avoid damage. At the same time, attention should be paid to avoiding direct contact between copper slip rings and corrosive media to prevent corrosion.

Replacement precautions: When the conductive brush or conductive plate of the copper slip ring is worn to a certain extent, it should be replaced in a timely manner. During the replacement process, it should be ensured that the model and specifications of the new copper slip ring are consistent with those of the original copper slip ring to ensure its stability and reliability in performance.

Storage precautions: When storing copper slip rings, they should be placed in a dry and ventilated environment to avoid prolonged exposure to moisture or high temperatures. At the same time, it should be ensured that the packaging of the copper slip ring is intact and undamaged to avoid damage during storage.

In summary, Copper Slip Ring is a sliding electrical contact element with excellent conductivity, wear resistance, and corrosion resistance. It has been widely used in various fields such as aerospace, military equipment, industrial automation, medical equipment, and transportation. In order to ensure the stability and reliability of copper slip rings, regular maintenance and upkeep are necessary, and attention should be paid to relevant matters during installation, use, and replacement.