Definition

Definition

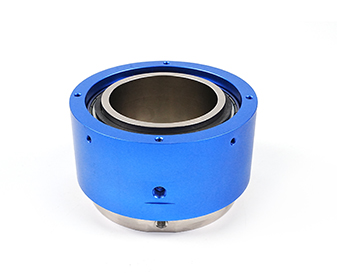

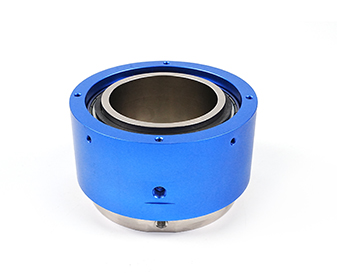

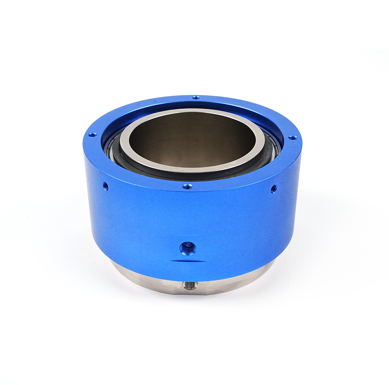

Large Diameter Slip Ring is a rotating electrical connection device used to transmit power, signals or data. It usually consists of conductive rings, brushes (or contact brushes), insulating materials and housings, and can provide reliable electrical connections between rotating and static components. Due to its special structure and design, large-diameter slip rings can withstand larger currents and higher data transmission rates, and are suitable for various application scenarios that require rotating electrical connections.

Characteristics

Large diameter design: The distinguishing feature of a large diameter slip ring is its larger diameter, which allows it to accommodate more conductive rings and brushes, thereby supporting higher current and data transfer rates.

High reliability: The large-diameter slip ring uses advanced contact technology and materials to ensure the stability and reliability of the electrical connection during rotation.

Long service life: Through optimized design and selection of wear-resistant materials, large-diameter slip rings can withstand long-term rotation and friction, extending service life.

Multi-channel transmission: Large-diameter slip rings support simultaneous transmission of multiple conductive rings to meet a variety of signal and data transmission needs in complex systems.

Flexible customization: According to specific application requirements, large-diameter slip rings can flexibly customize the number, material, size and other parameters of conductive rings.

Function

Power transmission: Large-diameter slip rings can transmit high-power power to meet the power supply needs of rotating parts.

Signal transmission: Supports the transmission of analog and digital signals, including audio, video, control signals, etc.

Data transmission: Supports high-speed data transmission, such as Ethernet, USB, etc., to meet the data communication needs of modern electronic equipment.

Rotating connection: Provides reliable electrical connection between rotating and static components, enabling signal and data transmission between rotating and static components.

Application areas

Aerospace: In aerospace vehicles such as aircraft and satellites, large-diameter slip rings are used to transmit power and signals to support the operation of flight control systems.

Military equipment: In military equipment such as tanks and armored vehicles, large-diameter slip rings are used to transmit power and signals of weapon systems to ensure the normal operation of the equipment.

Industrial automation: In industrial automation equipment such as robots and automated production lines, large-diameter slip rings are used to transmit power and signals to support the rotation and movement of the equipment.

Medical equipment: In medical equipment such as CT machines and MRIs, large-diameter slip rings are used to transmit image data and power to support the rotation and scanning operations of the equipment.

Energy field: In energy fields such as wind power generation and solar power generation, large-diameter slip rings are used to transmit power and signals to support power supply and signal transmission of rotating parts.

Maintenance and maintenance

Regular inspection: Regularly inspect large-diameter slip rings, including conductive rings, brushes, insulating materials and shells, to ensure that no parts are damaged or loose.

Cleaning and maintenance: Use a soft cloth or brush to clean the surface of the large-diameter slip ring and the brush to remove dust, oil and other impurities, and keep it clean and dry.

Lubrication treatment: Apply an appropriate amount of lubricant between the brush and the conductive ring to reduce friction and wear and improve the stability and reliability of the electrical connection.

Avoid overloading: When using large diameter slip rings, avoid exceeding their rated current and voltage range to avoid damage to the conductive rings and brushes.

Prevent vibration: When installing and using large-diameter slip rings, take appropriate measures to prevent vibration and impact to avoid damage to the slip ring.

Precautions

Installation requirements: When installing large-diameter slip rings, installation should be carried out in strict accordance with the product instructions and installation requirements to ensure correct and firm installation.

Usage environment: Large-diameter slip rings should be installed in a dry, ventilated, and non-corrosive gas environment to avoid damage to them by harsh environments such as moisture, high temperature, and low temperature.

Protective measures: When protection is required, appropriate protective measures should be taken, such as installing protective covers, dust covers, etc., to protect the large-diameter slip rings from interference and damage from the external environment.

Replacement cycle: According to the usage and life of the large-diameter slip ring, wearing parts such as conductive rings and brushes should be replaced regularly to ensure its long-term stable operation.

Professional training: Personnel who use and maintain large-diameter slip rings should receive professional training to understand the structure, performance and usage of the product, and master correct maintenance and care skills.

In summary, large-diameter slip rings, as an important rotating electrical connection device, have broad application prospects in aerospace, military equipment, industrial automation, medical equipment and energy fields. During use, maintenance and upkeep should be carried out in strict accordance with the product instructions and maintenance requirements to ensure its long-term stable operation. At the same time, attention should also be paid to issues such as the use environment, protective measures, and replacement cycles to extend its service life and improve its use effect.