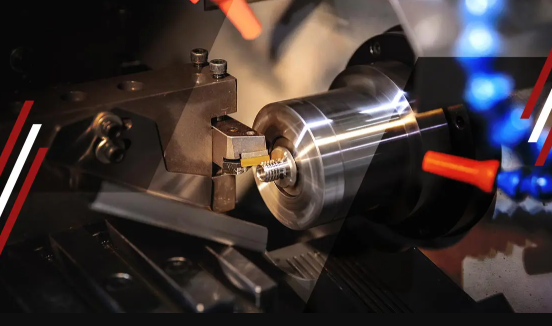

In modern CNC (Computer Numerical Control) machining, precision, speed, and reliability are key to achieving high-quality results. One of the critical aspects of CNC lathes is the efficient transmission of various signals necessary for controlling and monitoring the machine's components. Conductive slip rings provide a practical and reliable solution for signal transmission, ensuring that CNC lathes can operate smoothly and efficiently. This article explores how conductive slip rings contribute to signal transmission in CNC lathes, focusing on their ability to handle multi-channel signals and high-speed data transfer.

Multi-Channel Signal Transmission

CNC lathes require the simultaneous transmission of multiple signals to control various parts of the machine. These signals include motor control signals, feedback from sensors, temperature readings, and encoder signals. Conductive slip rings play a crucial role in this by offering multiple channels that can transmit different types of signals concurrently.

For instance, a 12-channel conductive slip ring can meet the needs of a CNC lathe's diverse signal transmission requirements. Each channel can be dedicated to specific tasks, such as transmitting encoder signals to accurately control the position of tools and the speed of the spindle, or transmitting temperature sensor signals to monitor the operational temperature of critical components. By allowing multiple signals to pass through a single slip ring, these devices reduce the complexity of wiring systems and improve the overall efficiency of the machine.

In complex CNC lathe control systems, some signals are analog while others are digital. Conductive slip rings are designed to effectively handle both types of signals, ensuring accurate signal transmission. Special shielding and design considerations in the slip ring prevent electromagnetic interference from distorting analog signals. This feature ensures that signals are transmitted cleanly, just like creating a "dedicated lane" for data to travel through without being affected by external "noise."

High-Speed Signal Transmission

Another critical requirement for CNC lathes is high-speed signal transmission, particularly when the machine is operating at high speeds. To meet these demands, conductive slip rings are engineered to optimize the contact structure between the brushes and conductive rings, reducing resistance and friction.

Using high-quality materials such as gold-alloy brushes in combination with precision-engineered conductive rings, conductive slip rings can provide smooth and reliable signal transfer even at high rotational speeds. This design ensures that the signal remains stable, free from interruptions or delays, even when the lathe's spindle is spinning at high velocities. In this way, CNC operators can trust that the machine's feedback and control systems are accurately synchronized, no matter how fast the machine is running.

Moreover, the electrical design of the conductive slip ring is key to achieving high-speed data transmission. The use of advanced high-frequency circuit design techniques helps ensure that the impedance of the transmission lines is optimized, minimizing signal reflection and loss. This is similar to creating a "highway" for signals to travel through, where data can flow smoothly and without obstruction, ensuring the integrity and speed of the transmission.

Ensuring Signal Integrity

Signal integrity is a primary concern in CNC machining environments, where even the slightest disruption in the signal can lead to operational errors or reduced machining accuracy. Conductive slip rings are designed to maintain the integrity of the transmitted signals, particularly in environments where the machine is subject to vibrations, thermal expansion, and other mechanical stresses.

In CNC lathes, the reliability of signal transmission is critical for the precise operation of sensors, actuators, and motors. Conductive slip rings are built to withstand these challenges, offering robust performance even under harsh conditions. With their ability to deliver consistent and stable signal transfer, conductive slip rings ensure that CNC lathes operate at peak efficiency, minimizing downtime and enhancing overall productivity.

Conclusion

Conductive slip rings are a vital component in the operation of CNC lathes, offering efficient solutions for multi-channel signal transmission and high-speed data transfer. By supporting the seamless transmission of both analog and digital signals, slip rings ensure that CNC lathes can perform complex tasks with precision and reliability. The ability to transmit multiple signals through a single slip ring, combined with high-speed transmission capabilities and enhanced signal integrity, makes them indispensable in modern machining systems. With the continued advancements in slip ring technology, manufacturers can be confident that their CNC machines will operate at optimal performance, meeting the demanding requirements of today’s precision manufacturing processes.

The company for automation equipment, new energy equipment, heavy machinery, industrial robots, military, aviation, medical equipment, wind power generation, scientific research institutes, etc., to provide a variety of high-precision conductive slip rings and technical support. Mature and perfect solutions and reliable quality, highly recognized in the industry, to become a variety of high requirements, high precision conductive slip ring manufacturers.