In the world of CNC machining, precision and reliability are paramount. CNC machines, especially those equipped with rotating components such as rotary tables or tool changers, require seamless electrical connections to ensure efficient operation. One common problem faced in these types of machines is the issue of wires tangling during rotation, which can severely disrupt operations, damage wiring, and affect signal integrity. The introduction of conductive Slip Rings has proven to be a game-changer in solving this problem, offering a more reliable and efficient solution.

The Wire Tangle Problem in CNC Machines

In CNC machines, electrical connections are necessary for powering rotating components and transmitting signals. However, traditional wire connections in rotating systems, without a proper mechanism for movement, often result in wires becoming twisted and tangled. This is especially problematic in machines with rotating tables, tool changers, and other parts that require continuous power or data transmission.

When wires tangle, it can lead to several issues:

Damage to Wiring: Constant rotation and tension on wires can cause them to fray, break, or become disconnected.

Signal Interference: Tangled wires may cause signal loss or interference, affecting machine performance, leading to operational delays or even downtime.

Machine Malfunctions: In some cases, tangled wires can obstruct mechanical movement, resulting in machine errors or failure to perform tasks accurately.

These problems not only lead to increased maintenance costs but can also negatively affect the overall performance and productivity of the CNC machine.

The Role of Conductive Slip Rings in Preventing Wire Tangles

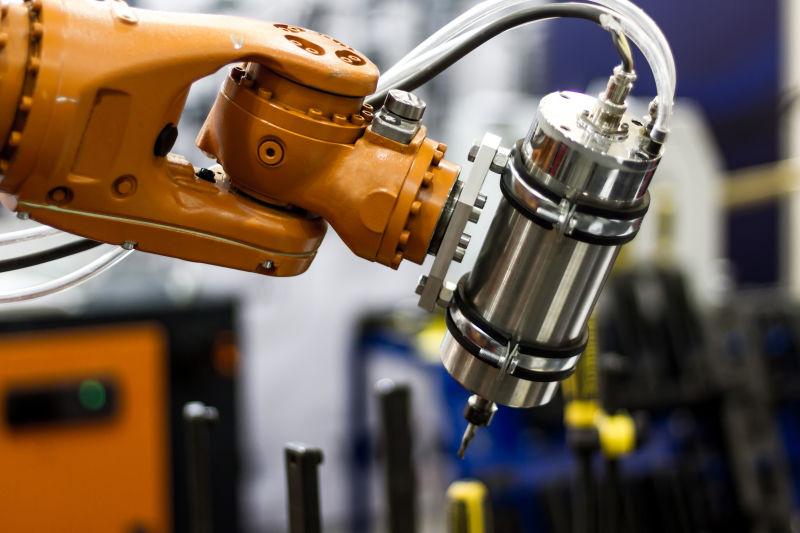

Conductive slip rings are specialized devices designed to facilitate the continuous transfer of electrical signals and power between stationary and rotating parts of a machine. Unlike traditional wiring systems, conductive slip rings offer a smooth and reliable connection by utilizing a rotary electrical contact mechanism.

The key feature of conductive slip rings that addresses the wire tangle issue is their sliding contact design. The rotating component of the machine, such as a rotary table or tool changer,

The company for automation equipment, new energy equipment, heavy machinery, industrial robots, military, aviation, medical equipment, wind power generation, scientific research institutes, etc., to provide a variety of high-precision conductive slip rings and technical support. Mature and perfect solutions and reliable quality, highly recognized in the industry, to become a variety of high requirements, high precision conductive slip ring manufacturers.