In modern CNC machining, auxiliary equipment plays a crucial role in ensuring optimal performance and efficiency. Machines such as cooling pumps and chip removal systems are essential in maintaining the precision and quality of operations. These systems require reliable power transmission, and conductive Slip Rings provide an effective solution by delivering uninterrupted electrical power to these devices while allowing continuous rotation.

The Role of Auxiliary Equipment in CNC Machining

CNC machines, particularly turning lathes, often rely on several auxiliary devices that enhance the functionality of the machine. Among the most critical are cooling pumps and chip removal systems. Cooling pumps circulate coolant fluid during machining, preventing overheating of the tool and workpiece. Chip removal systems, on the other hand, remove metal chips generated during the cutting process, ensuring the workspace remains clean and the machine operates smoothly.

Both of these devices require a stable and uninterrupted power supply to function properly, especially when the machine is in continuous motion. This is where conductive Slip Rings come into play, providing an essential power transfer solution.

Conductive Slip Rings for Power Transmission

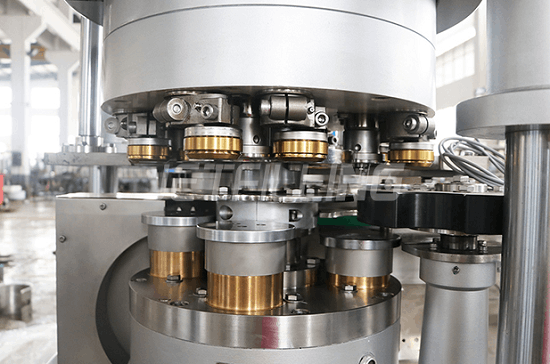

A conductive slip ring is a rotating electrical connector that allows the transfer of power and data between stationary and rotating parts of a machine. In CNC systems, slip rings can be integrated to supply power to auxiliary equipment, such as the cooling pumps and chip removal systems.

Take the cooling pump as an example. The cooling pump is typically powered by a three-phase alternating current (AC) source. A conductive slip ring can transmit this AC power to the pump motor, ensuring that the coolant continuously circulates during the machining process. This uninterrupted circulation is crucial for cooling the cutting tools and workpieces, thus preventing overheating and ensuring precision in machining operations.

Similarly, for chip removal systems, the slip ring provides the necessary electrical power to the chip evacuation motors. As the CNC machine works, metal chips accumulate in the cutting area, potentially obstructing the machine’s functionality. The slip ring ensures that the chip removal system operates continuously, preventing the build-up of debris and maintaining the cleanliness of the workspace.

Efficient Design and Integration of Power and Signal Transmission

One of the advantages of using conductive slip rings in CNC machines is their ability to manage both power and signal transmission through a single system. A well-designed slip ring can carry power for the auxiliary equipment while simultaneously transmitting signals for control and monitoring. This creates a compact and efficient transmission system, reducing the complexity and potential for failure.

For instance, the slip ring can be configured to handle both the three-phase power supply for the cooling pump and chip removal systems, as well as data signals used to monitor system performance. This dual-function capability allows for more streamlined and reliable operation of auxiliary equipment, enhancing the overall performance of the CNC machine.

Conclusion: Ensuring Continuous Operation of Auxiliary Equipment

Conductive slip rings are an invaluable component in the world of CNC machining. They offer a reliable and efficient method of transferring power to auxiliary equipment such as cooling pumps and chip removal systems. By ensuring that these devices receive uninterrupted power, conductive slip rings help maintain the stability and efficiency of the machining process, ensuring the optimal performance of CNC machines.

At OBABO, we specialize in providing custom conductive slip rings tailored to the specific needs of your systems. Whether you need a solution for a single piece of equipment or a more complex setup involving multiple power and signal transmission channels, we have the expertise to deliver high-quality, durable, and efficient solutions.

If you're looking to improve the power supply to your CNC machine's auxiliary devices, contact OBABO today to learn more about our conductive slip ring solutions.

The company for automation equipment, new energy equipment, heavy machinery, industrial robots, military, aviation, medical equipment, wind power generation, scientific research institutes, etc., to provide a variety of high-precision conductive slip rings and technical support. Mature and perfect solutions and reliable quality, highly recognized in the industry, to become a variety of high requirements, high precision conductive slip ring manufacturers.