Definition

Capsule Slip Ring, is a specially designed type of Slip Ring with a compact appearance and structure, suitable for various occasions that require rotating transmission of signals or energy. Slip Rings, also known as collector rings, rotary joints, rotary electrical interfaces, slip rings, collector rings, return loops, coils, commutators, converters, etc., are precision transmission devices that enable image, data signal, and power transmission between two relative rotating mechanisms.

Characteristics

Compact design: The hat shaped slip ring has a small volume, light weight, and is easy to install and integrate into various devices.

High transmission accuracy: The internal contacts adopt advanced surface treatment technology to ensure extremely low contact resistance and long working life.

Stable signal transmission: capable of accurately transmitting various signals such as Ethernet, USB, RS, Canbus, as well as servo motor signals, encoder signals, etc., suitable for various data transmission needs.

Flexible rotation: allows the device to maintain continuous transmission of signals and energy while rotating, without being limited by the rotation angle.

High reliability: Using high-quality materials and advanced manufacturing processes to ensure stable operation of the cap slip ring in various harsh environments.

Function

The main function of a hat type slip ring is to achieve signal and energy transmission between rotating and fixed components. Specifically, it can keep the current of the fixed wire in contact with the wire that needs to be rotated or rotated, ensuring that the rotating equipment can continuously receive power and signals during the rotation process. In addition, the cap type slip ring also has the following functions:

Preventing wire entanglement: In rotating equipment, wires are prone to entanglement due to rotation, leading to equipment failure. The hat shaped slip ring transmits signals and energy through rotation, avoiding the problem of wire entanglement.

Improving equipment performance: Hat shaped slip rings can ensure stable signal and energy transmission of rotating equipment during rotation, thereby enhancing equipment performance and stability.

Simplify equipment structure: Using cap type slip rings can simplify the structure of rotating equipment, reduce manufacturing and maintenance costs.

Application Fields

Hat shaped slip rings are widely used in various situations that require rotational transmission of signals or energy due to their unique characteristics and functions. Here are some typical application areas:

Security monitoring: In security monitoring systems, cameras need to rotate to monitor different areas. The hat shaped slip ring can ensure stable signal transmission of the camera during rotation, thereby achieving continuous monitoring.

Factory automation: In factory automation production lines, various rotating equipment needs to transmit signals and energy to complete production tasks. Hat shaped slip rings can meet the transmission needs of these devices and improve production efficiency.

Medical equipment: In medical devices such as CT scanners, MRI, etc., cap type slip rings are required to transmit scanning data and power signals to ensure the normal operation of the equipment.

Aerospace: In the aerospace field, various aircraft and satellites require the use of cap slip rings to transmit control signals and power signals for precise flight control and data transmission.

Robot technology: In robot technology, robot joints need to rotate to complete various actions. The hat shaped slip ring can ensure stable signal and energy transmission during the rotation of the robot, thereby improving its performance and stability.

Parameter Drawings

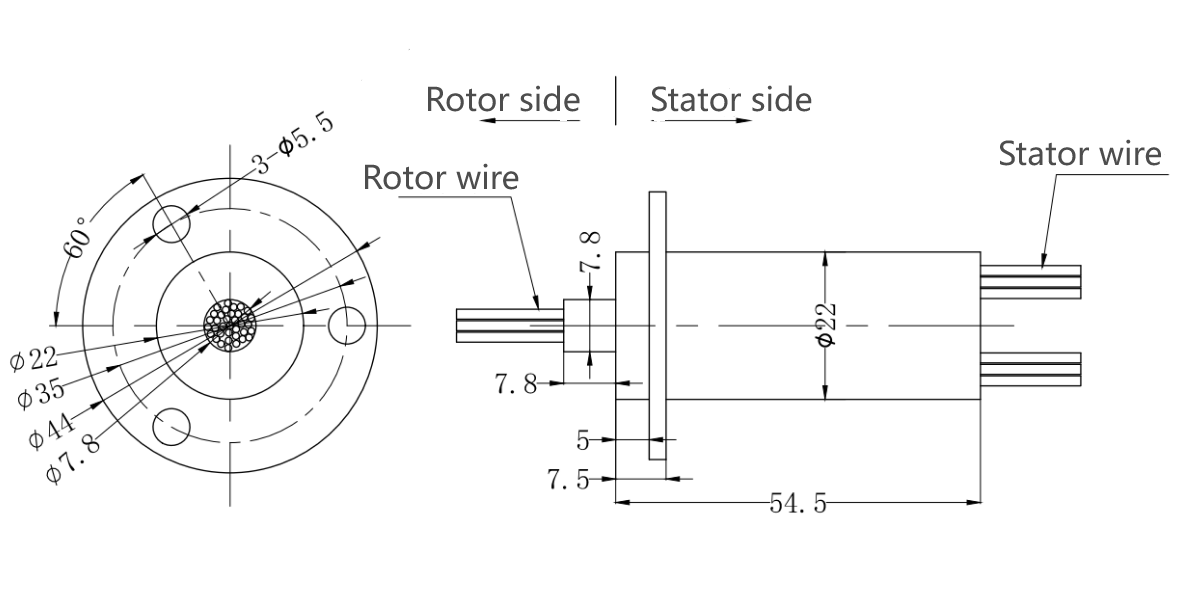

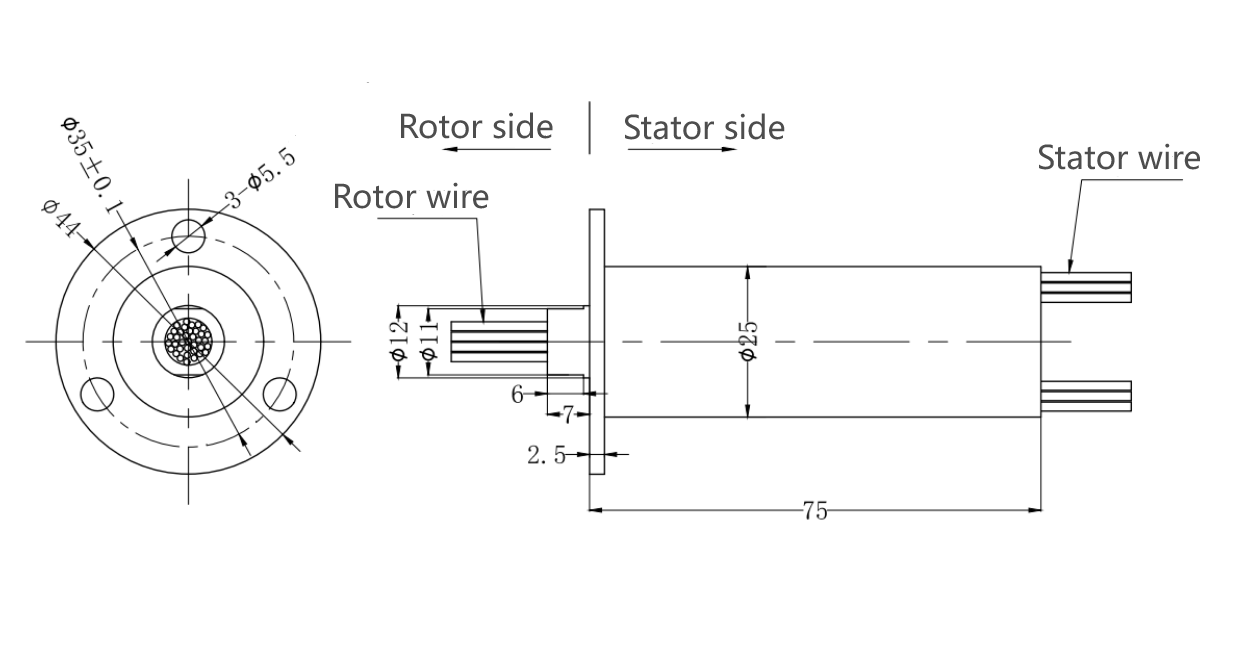

Capsule Slip Ring XC36-F

Capsule Slip Ring XC36-F

Maintenance and upkeep

In order to ensure the long-term stable operation of the hat type slip ring, regular maintenance and upkeep are required. Here are some recommended maintenance and upkeep measures:

Regular inspection: Regularly inspect the appearance and performance of the cap type slip ring to ensure that it is in good working condition. If any abnormalities or damages are found, they should be repaired or replaced immediately.

Cleaning and maintenance: Regularly clean the surface and internal contacts of the cap type slip ring to remove impurities such as dust and dirt. Specialized cleaning agents or alcohol can be used for cleaning, but highly corrosive cleaning agents should be avoided.

Lubrication treatment: Apply an appropriate amount of lubricant to the rotating part of the cap type slip ring to reduce friction and wear. But attention should be paid to selecting suitable lubricants to avoid using incompatible lubricants that may cause equipment failure.

Avoid overload: When using cap type slip rings, it is important to avoid exceeding their rated load and speed range to prevent equipment damage or performance degradation.

Storage environment: When storing cap type slip rings, they should be placed in a dry, ventilated, and non corrosive gas environment to avoid moisture, corrosion, or damage.

Precautions

When using a hat type slip ring, the following precautions should be taken to ensure its normal operation and extend its service life:

Correct installation: When installing the cap type slip ring, it should be installed correctly according to the product manual or professional guidance. Ensure accurate installation position, firm fixation, and avoid damaging the slip ring during installation.

Avoid vibration and impact: When using cap type slip rings, strong vibration and impact should be avoided. These factors may cause the internal contacts of the slip ring to become loose or damaged, thereby affecting its performance and service life.

Pay attention to temperature range: The working temperature range of the cap type slip ring is limited. When using, attention should be paid to avoiding exceeding its maximum operating temperature range to prevent equipment damage or performance degradation.

Choose the appropriate model and specifications: When selecting a hat type slip ring, the appropriate model and specifications should be chosen based on specific application and equipment requirements. Ensure that the selected slip ring can meet the transmission requirements and working conditions of the equipment.

Follow safety regulations: When using cap type slip rings, relevant safety regulations and operating guidelines should be followed. Ensure the safety of operators and avoid equipment damage or personnel injury caused by improper operation.

In summary, Capsule Slip Ring is a powerful and widely used electrical connection device. By understanding its characteristics, functions, application areas, as well as maintenance and upkeep methods, the hat type slip ring can be better utilized to provide stable and reliable signal and energy transmission solutions for various rotating equipment.